Environmental Engineering Reference

In-Depth Information

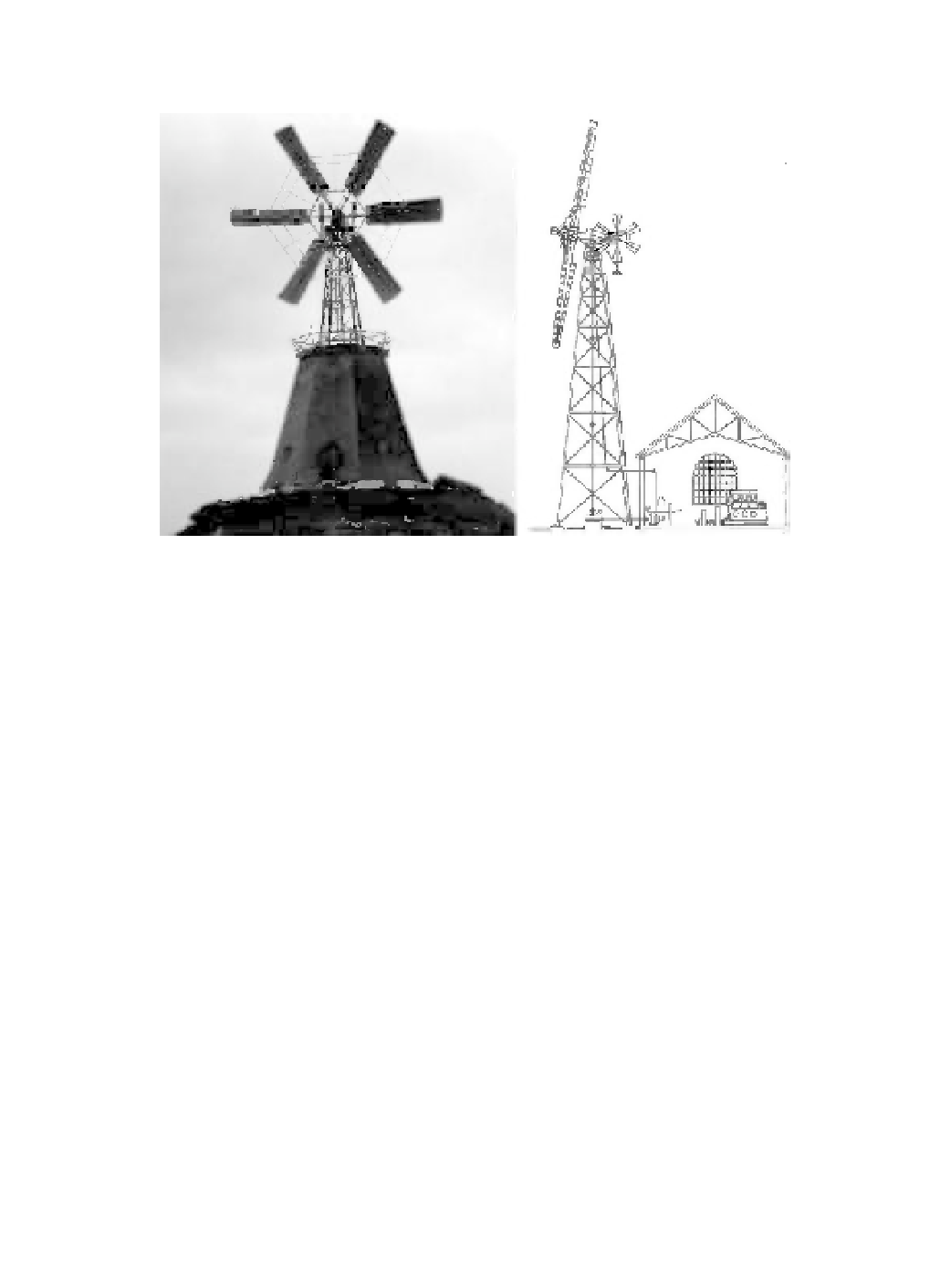

generation. During more than 50 years (until 1957), the Lykkegaard

factory produced 4-bladed windmills true to the la Cour tradition.

Figure 3.15

In 1922, the turnable cap and big 4-bladed wooden rotor

on this traditional windmill was replaced by a steel lattice

tower and a 6-bladed rotor similar to the type used on

the popular farm windmills. The local manufacturer D. M.

Heide made this kind of modification on 20 of the 31

commercial grain windmills on the island Mors (Photo: Morsø

Local Historical Archives) (left). The Lykkegaard Machine

Factory maintained production between the two world wars

by export and by “leasing-arrangements” with small local

power stations. The 4-bladed windmills for these projects

were true to the Poul la Cour tradition (Picture: The Danish

Energy Museum) (right).

During the difficult decades after the First World War,

Lykkegaard ofered small local power stations to install a windmill

and ensure its operation. The local power plant had to guarantee

for a loan of 80% of the value of the windmill and be responsible

for the daily operation. Lykkegaard did service, repair work and

replacement of parts and demanded a fixed price for each kWh

the windmill generated. In a good windy location, this arrangement

could be a good deal for both parts.

Search WWH ::

Custom Search