Environmental Engineering Reference

In-Depth Information

Tests made in 1921-1924 by the Danish State Test Authority

showed that the Agricco used the wind energy with a much higher

efficiency than la Cour's “ideal” windmill. Several developers in

other European countries introduced windmills with aerodynamic

blades after the war, but the Agricco's position was also inter-

nationally documented with tests by the Institute of Agricultural

Engineering at the Oxford University [10]. In 1925, the manu-

facturing rights for the Netherlands, Argentine and Brazil were sold

to the firm Werkspoor in Amsterdam, which produced windmills

for the use with drainage pumps. In the same year a proposal for

production of the turbine was made in the United States [11].

However, as the market for windmills was in decline, the Danish

production closed in 1926 and it must be concluded, that the

Agricco was “the right windmill, but at the wrong time”.

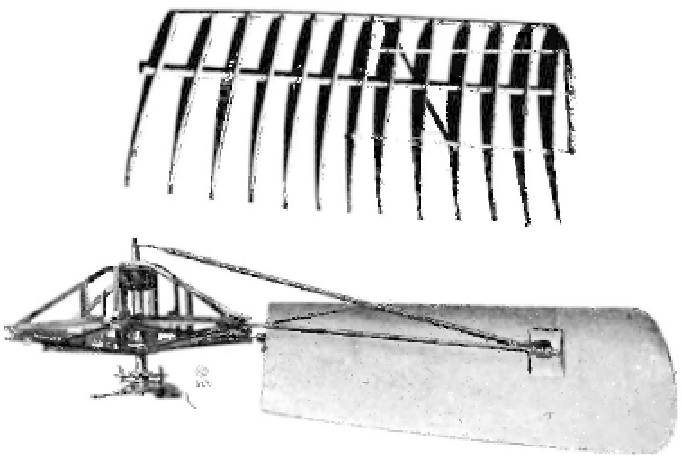

Figure 3.13

Pitch-regulated blades on the Agricco windmill had a steel tube

as the main structural element, wooden profiles and covering

of metal plate (Illustrations from a catalogue in The Danish

Energy Museum).

For the next two decades, the few remaining Danish windmill

producers used diferent survival strategies. From a complete

collection of notebooks from one of the medium-sized Danish

windmill producers, D. M. Heide on the island of Mors, the yearly

Search WWH ::

Custom Search