Environmental Engineering Reference

In-Depth Information

and extended to a full design series including DANmark 8 (13 kW),

DANmark 11 (22 kW), DANmark 17 (75 kW), DANmark 19 (95 kW),

DANmark 22 (150 kW), and the DANmark 25 (200-270 kW) (FC,

1990).

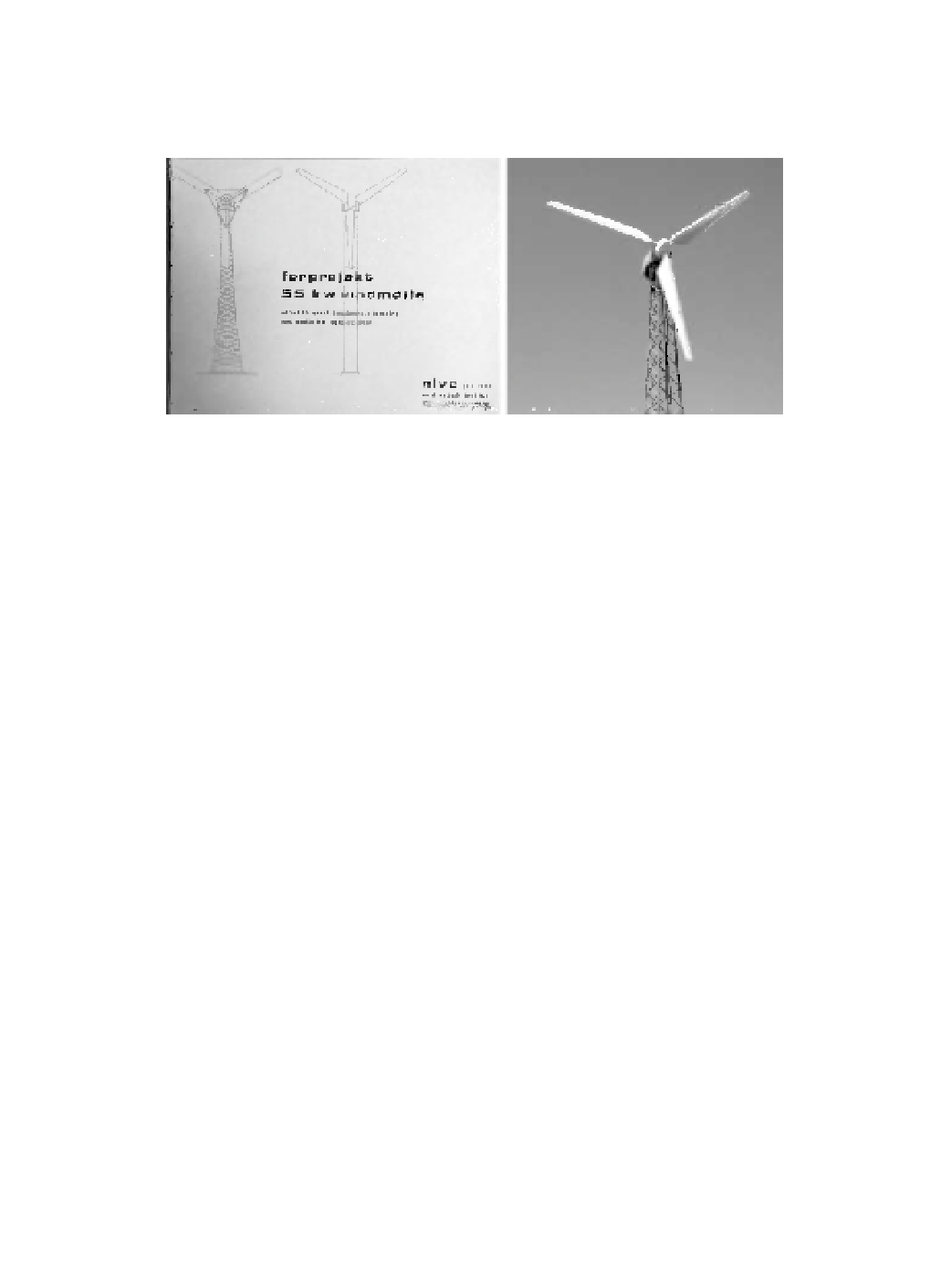

Figure 5.20

Project cover for the 55 kW DANmark wind turbine, NIVE,

1981 (left); DANmark 17 at the Folkecenter's Wind Test

Field (right) (Photo: Folkecenter).

From this beginning, all of the major Danish wind turbine

manufacturers of the 1980s through today can trace their origins to

this “Danish Concept” established at NIVE along with the Riisager

turbine development and based on the combination of Tvind and

Gedser turbine design concepts. The early companies, all working

with Økær, took advantage of the developing supply chain and

leveraged the design basis that had been established. Each new

company, however, brought to the table its own area of expertise

to improve component design and contribute to the overall Danish

wind turbine “supply chain” (Maegaard, 2009a; Maegaard, 2010).

For instance, one oversight of the first turbine designs had to do

with the omission of the blade tip brakes, which had been present on

the Gedser turbine in the 1950s. As Maegaard noted, for the Tvind

tower, they also omitted tip brakes and used parachutes brakes in

addition to blade pitch for an emergency stop mechanism—which

also made an upwind configuration prohibitive because for an

upwind system, the parachutes would hit the tower. The braking

system was one of the more challenging aspects of the first system

and in Maegaard's own words, the tip brakes “in the first [turbines]

were not considered. They were neglected. I can tellyou they were

really neglected… we did not read Juul carefully enough!” (Maegaard,

2010).

Search WWH ::

Custom Search