Environmental Engineering Reference

In-Depth Information

in great contrast to the case measured in pure ethanol, indicating a soft silica

surface in CTAC ethanol solutions. Considering all the details in this force

profile, we can interpret the observed jump-in being the removal of a single layer

of micelles from the gap between the tip and sample under the applied force of

AFM tip. It is therefore reasonable to conclude that the silica surface is covered

by CTACmicelles, and the size (diameter) of micelles or thickness of single layer

micelles on silica is around 5.7 nm.

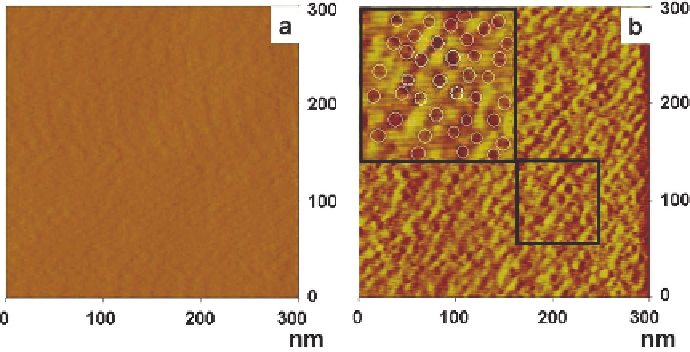

The AFM images of silica in ethanol and 5 mmol/L CTAC ethanol solution

are shown in Fig. 6.9a,b, respectively. The silica wafer in ethanol exhibits a

smooth, featureless topography (Fig. 6.9a). The image of silica wafer obtained

in CTAC ethanol solution (Fig. 6.9b), on the contrary, shows well-defined

features. It is interesting to note that the size of high spots is of 6 nm range, a

value very close to the jump-in distance observed on the force profile. It appears

that CTAC at 5 mmol/L concentration in ethanol forms pseudo-spherical

micelles. These micelles are assembled on silica surface with well-defined

voids of 10-nm diameter. For better view, a higher magnification image of the

marked area is shown on the left corner with circles to highlight the voids. By

filling in these voids with desired materials and removing the micelles, one can

obtain mesoporous surfaces of desired materials. Clearly these assembled

micelles can serve as templates for synthesis of mesoporous silica coatings on

silica-coated magnetic particles.

Structural properties of surfactants and micellar solutions are crucial when

preparing mesoporous structures. Surfactants in solution assemble into struc-

tures whose geometry can be described by the surfactant packing parameter [113,

114]. This packing parameter is defined as g=v/al, where n is the volume of the

surfactant tail, a is the effective head group area, and l is the length of the

extended surfactant tail. An increase in the packing parameter represents a

Fig. 6.9 Silica wafer in ethanol (a) and CTAC solutions (b)(circles represent voids to be filled

by silica using sol-gel method)