Biomedical Engineering Reference

In-Depth Information

30 Hz. Unfortunately, standard anodization breaks down in the presence of saline (e.g.,

from sweat), making the electrodes unreliable for long-term use.

A relatively new anodization process was used by Lisa Sagi-Dolev, the former head of

R&D at the Israeli Airforce Aeromedical Center, and one of us [Prutchi and Sagi-Dolev,

1993] to manufacture pasteless EEG electrodes that could be embedded in

flight helmets.

The hard anodization Super coating process developed by the Sanford Process Corporation

3

is formed on the surface of an aluminum part and penetrates in a uniform manner, making

it very stable and resistant. The main characteristics of this type of coating are hardness

(strength types Rockwell 50c-70c), high resistance to erosion (exceeding military standard

MIL-A-8625), high resistance to corrosion (complete stability after 1200 hours in a saltwa-

ter chamber), stable dielectric properties at high voltages (up to 1500 V with a coating thick-

ness of 50

fl

m), and high uniformity.

Hard anodization Super has been authorized as a coating for aluminum kitchen uten-

sils, and it proves to be very stable even under high temperatures and the presence of cor-

rosive substances used while cooking. The coating does not wear of

µ

m, and up to 4500 V with a coating thickness of 170

µ

with the use of

abrasive scrubbing pads and detergents. These properties indicate that no toxic substances

are released in the presence of heat, alkaline or acid solutions, and organic solvents. This

makes its use safe as a material in direct contact with skin, and resistant to sweat, body

oils, and erosion due to skin friction.

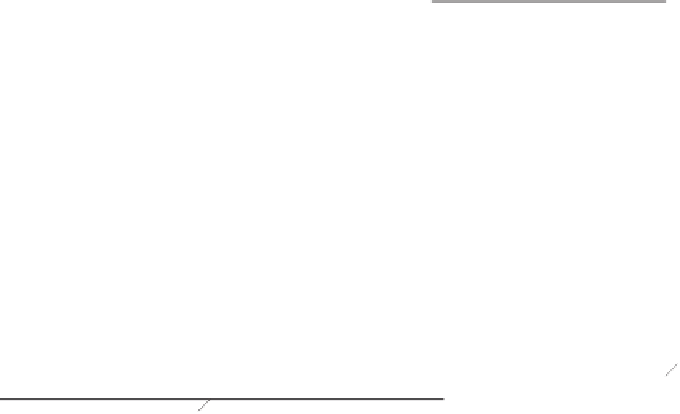

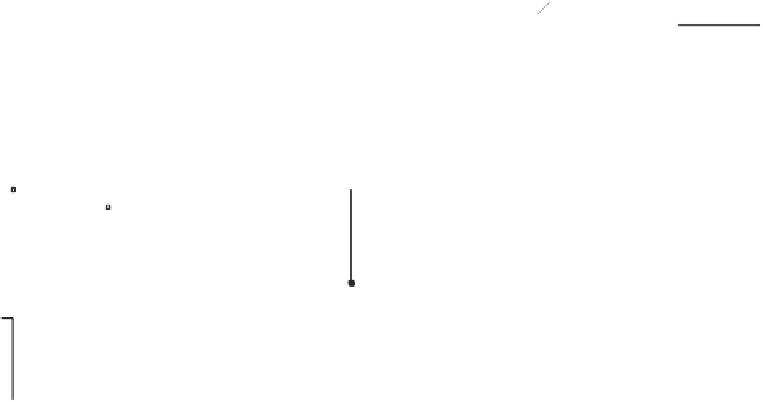

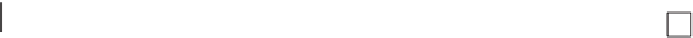

Figure 1.11 is a circuit diagram of a prototype active pasteless bioelectrode. The biopo-

tential source is coupled to bu

ff

ff

er IC1A through resistor R1 and the capacitor formed by

the biological tissues,

aluminum oxide dielectric,

and aluminum electrode plate.

Operational ampli

er and is used to transform

the extremely high impedance of the electrode interface into a low-impedance source that

can carry the biopotential signal to processing equipment with low loss and free of

fi

er IC1A is con

fi

gured as a unity-gain bu

ff

Flat

Cable

Driven

Shield

J1

1

+V

Anodized

Plate

J2

C2

0.01uF

R1

10K

1

-V

C3

0.01uF

IC1A

TL082

3

2

IC1B

R2

100

J3

8

8

5

6

+

+

7

1

1

Output

-

-

C1

5pF

R3

10K

TL082

4

4

Shield

Figure 1.11

Schematic diagram of a capacitive active bioelectrode. Biopotentials are coupled to buffer IC1A through resistor R1 and the

capacitor formed by the biological tissues, aluminum oxide dielectric, and aluminum electrode plate. Operational amplifier IC1A is configured

as a unity-gain buffer. IC1B drives a shield that protects the input from current leakage and noise. Resistors R3 and R2 reduce the gain of the

shield driver to just under unity to improve the stability of the guarding circuit. C1 limits the bandwidth of input signals buffered by IC1.

3

Hard anodization Super is a process licensed by the Sanfor Process Corporation (United States) to Elgat

Aerospace Finishing Services (Israel) and is described in Elgat Technical Publication 100,

Hard Anodizing:

“Super'' Design and Applications

.

Search WWH ::

Custom Search