Biomedical Engineering Reference

In-Depth Information

W

t

Surface Track

Layer 1

{

t

t

PCB

dielectric

Layer 2

{

buried

track

h

Layer 3

{

Ground

Plane

Layer 4

{

V

cc

Plane

Layer 5

{

Layer 6

{

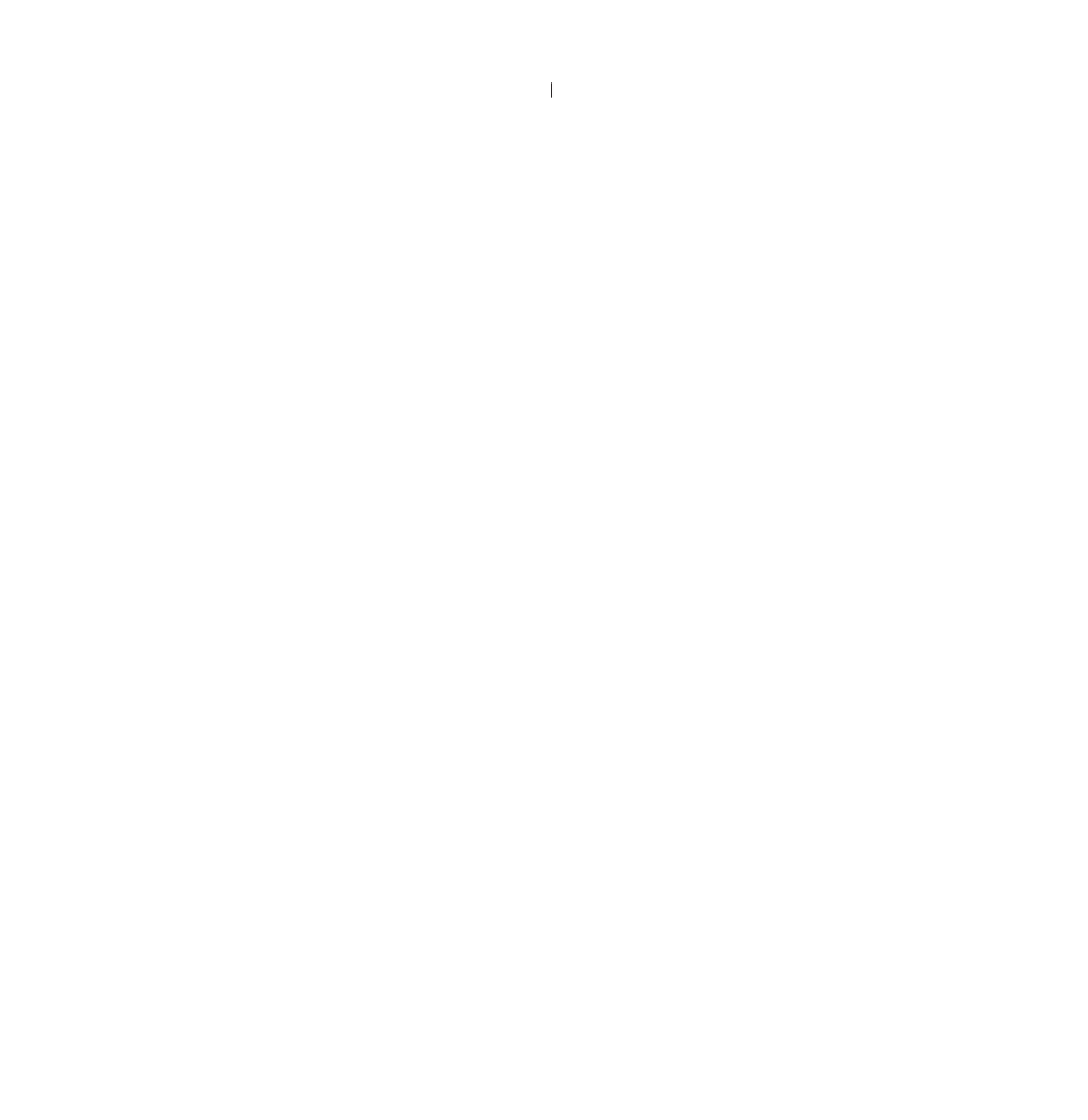

Figure 4.35

The transmission line impedance of a stripline PCB track is affected by its position relative to the ground or power plane as

well as by its geometry and by the dielectric constants of the board and the surrounding medium.

load impedance

Z

l

with a distorted version of the pulse, and presenting an e

ff

ective delay

τ

. On a typical surface PCB track, the pulse conduction velocity is approximately

0.15 ns/in.

0.06 ns/cm, so

τ

0.15

l

t

(ns) represents the total delay caused by a track of

length

l

t

(measured in inches).

If the load impedance does not match the track's impedance perfectly, a part of the

arriving signal will be re

fl

ected back into the transmission line. In general, pulse re

fl

ection

occurs whenever transmission lines with di

erent impedances are interconnected or when

a discontinuity occurs in a single transmission line. For a connection between two trans-

mission lines of impedances

Z

0

and

Z

1

, the re

ff

fl

ected voltage

V

r

is related to the incident

voltage

V

i

through

Z

Z

Z

Z

1

1

0

0

V

i

V

r

The ratio

Γ

V

r

/

V

i

, called the

re

fl

ection coe

cient

, describes what portion of the pulse

incident from

Z

0

on

Z

1

will be re

,

V

i

, and

V

r

are usually complex

quantities because they deal with both the magnitude and phase of the signals that travel

along transmission lines.

Using tracks buried within the PCB between the power and ground planes is an

fl

ected back into

Z

0

.

Γ

e

ective way of controlling RFI and ESD threats. In contrast with one- or two-sided

PCBs, multilayered PCBs with ground and power planes keep ground impedances and

loop lengths su

ff

cant levels of

RFI. Typically, PCBs with signal tracks sandwiched between ground and power planes

are a full order of magnitude less sensitive to RFI than are well-designed two-sided

boards.

For nonmedical equipment, the power and ground planes are usually grounded to the

chassis. In medical equipment, however, it is usually the most sensitive circuits that need

to

ciently low to avoid circuit tracks from picking up signi

fi

float, making it impossible to apply classical EMC techniques for proper signal-path

decoupling and shielding. For

fl

floating circuits that end up being sensitive to EMI, try to

form a capacitive grounding path between the power and ground planes of the PCB and

fl

Search WWH ::

Custom Search