Biomedical Engineering Reference

In-Depth Information

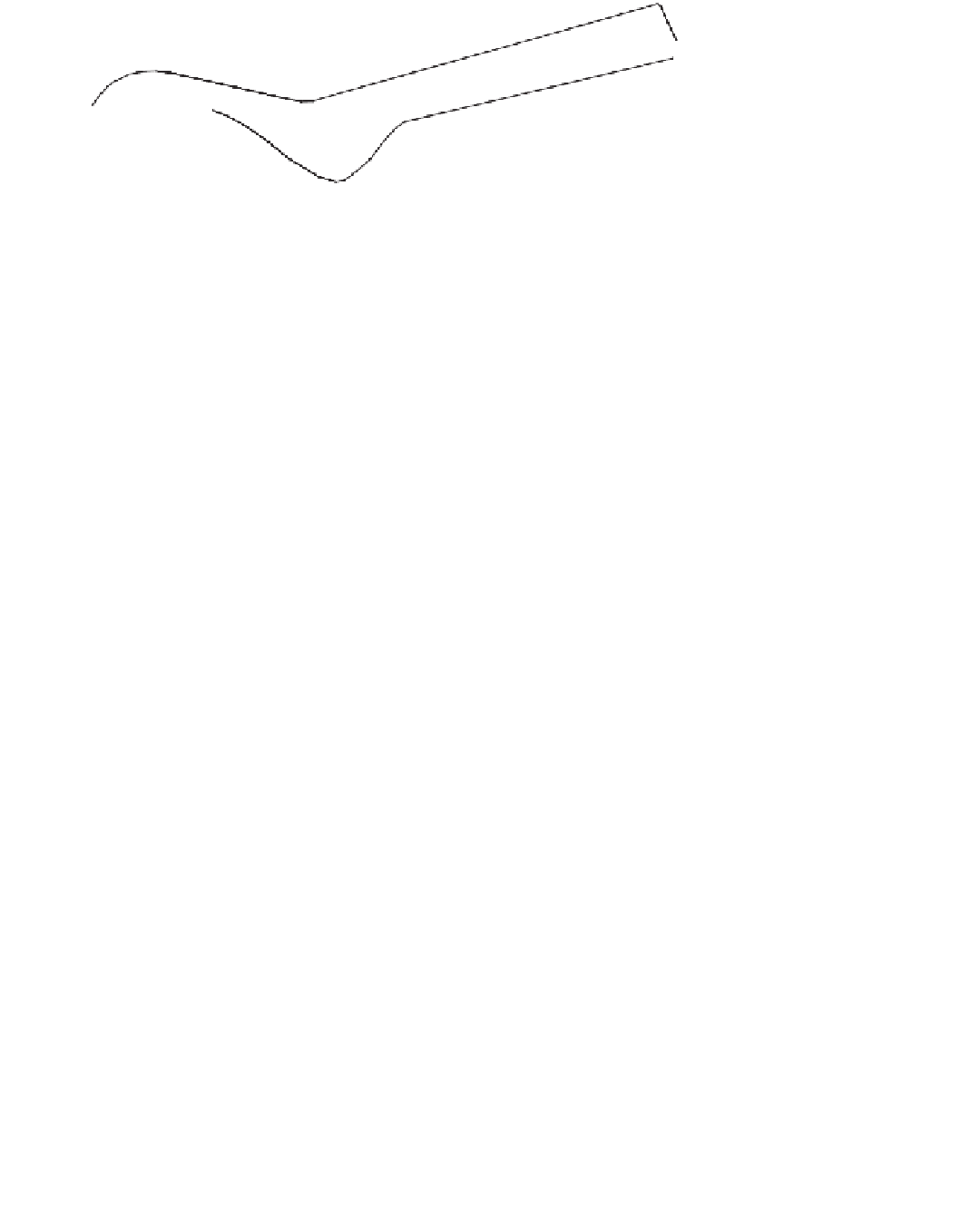

Voltage-Measurement

Jaw

Heat-Shrink

Tubing

Nylon Bolt

and Nuts

Spring

Lead to J3

Dielectric

Separator

Lead to J2

Current-Injection

Jaw

Figure 3.22

An alligator clip can be converted into a Kelvin probe by replacing the standard metallic axis by a nylon bolt with nylon

spacers to isolate the jaws from each other. For the same reason, the ends of the inner spring must also be insulated.

suitable insulator. Two separate leads are then used to connect to the jaws of the probe, one

to inject current and the other to sense voltage.

Once the circuit and the probe are assembled, calibrate the adapter to produce exactly 1 A.

Plug the power cord of the instrument under test to the hospital-grade ac plug J1, and clip the

Kelvin probe to an exposed conductive point of the case that is supposed to be protectively

grounded. A digital voltmeter connected between J4 and J5 will directly read the protective

ground resistance on a scale of 1 V/

. It must be remembered, however, that the measure-

ment of resistance provided by this instrument only approximates the impedance test intended

by the standards. The discrepancy between the methods is especially evident for high-power

circuits, since a dc measurement of resistance does not convey any information regarding the

inductive component of impedance. Moreover, dc ohmmeters are usually fooled by the polar-

ized interface that results when an oxidation layer forms between connections in a defective

ground system. This last concern may be alleviated by running the test once again but with

the current injection polarity reversed. Nonlinear polarization indicating oxidation must be

suspected if resistance measurements taken with opposite current injection polarities do not

agree to a high degree. Failing this test is an immediate show-stopper. Before proceeding

with any further testing, you must locate the faulty connection responsible for compromis-

ing the integrity of the protective ground.

Measuring Leakage and Patient Auxiliary Currents

Leakage and auxiliary current tests are the most important tests to establish the electrical

safety of a medical electronic instrument. These are also the tests that are most commonly

failed during safety approval submissions as well as during the periodic tests that hospitals

conduct to ensure the safety of medical electronic devices throughout their service life. In

the case of medical electronic instruments, measurements of leakage and auxiliary currents

are taken using a load that simulates the impedance of a human patient. The

AAMI load

is

a simple

RC

network that presents an almost purely resistive impedance of 1 k

for fre-

quencies up to 1 kHz. As shown in Figure 3.23

a

, this load constitutes the core of the cur-

rent measuring device. If a 1-

erent

frequencies, the high-impedance RMS voltmeter within the measuring device would read

the values presented in the graph of Figure 3.23

b

.

A current is forced through the AAMI load at di

ff

Search WWH ::

Custom Search