Biomedical Engineering Reference

In-Depth Information

TABLE 3.1 Spacings (Millimeters) Required to Provide Various Levels of Insulation

between Parts of a Medical Device

Ac Voltage:

125 V

250 V

380 V

Dc Voltage:

150 V

300 V

450 V

Basic insulation (between

Air clearance

1

1.6

2.4

parts of opposite polarity)

Creepage distance

2

3

4

Double or supplementary

Air clearance

1.6

2.5

3.5

insulation

Creepage distance

3

4

6

Double or reinforced

Air clearance

3.2

5

7

Reinforced insulation

Creepage distance

6

8

12

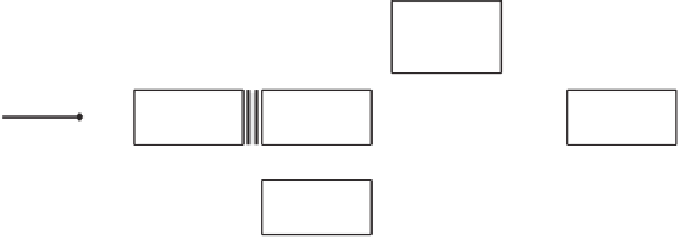

Figure 3.1 and Table 3.1 present a partial view of how to achieve the minimal required

insulation ratings between parts. Although these are only a subset of all possibilities contem-

plated by the standards, they certainly provide a very practical reference for the designer.

LEAKAGE CURRENTS

Evidently, the purpose of the various isolation barriers is to ensure that leakage currents

are maintained within safe values even when a single-fault condition occurs. Three types

of leakage currents are de

fi

ned within the standards:

MEDICAL

INSTRUMENT

Input/Output

Part with

Connection to

Ground

R

S

B

B

AC Power

R

Patient Connections

Floating-Type

Applied Part

Live Part

(Mains Part)

Live Part

B

R

S

Non-Live Part

R

B

Conductive Enclosure

Connected to Protective Ground

Figure 3.1

Some of the requirements for insulation between the parts of a medical instrument. Insulation types: B, basic; S, supplementary;

R, reinforced.

Search WWH ::

Custom Search