Biomedical Engineering Reference

In-Depth Information

for the maximum Lyapunov exponent

l

, which characterizes the degree of chaos in the mixer. Due to

stretching and folding, the penetration distance between two fluid streams can be estimated as:

d

¼

W

y

exp

ð

lt

Þ

(7.31)

Thus, the required channel length for this type of micromixer can be estimated as:

d

2

u

2

D

¼

u

2

D

exp

W

y

L

mixer

¼

ð

2

lt

Þ:

(7.32)

Bottausci et al.

[14]

implemented the concept depicted in

Fig. 7.11

in a silicon/glass device. Three

pairs of disturbance channels were used in this design. The disturbance velocities were generated by an

external pump. The mixing channel is 200

m

m wide, 100

m

m deep, and 1300

m

m long. Full mixing can

be achieved within 0.1 second in this micromixer.

Tabeling et al.

[15]

reported a mixer with only one pair of disturbance channels. The device was

fabricated in a PDMS/PDMS/glass stack. The flow in the two disturbance channels are controlled by

pneumatic valves, which alternately open and close. The valve actuation induces the periodic

disturbance. Pressure supply to the pneumatic valves was controlled by external valves, which

determine the switching frequency of the disturbance. The same device was characterized for

spatiotemporal resonances by Dodge et al.

[6]

. Instead of using folding quality as depicted in

Fig. 7.4

,

the time-averaged variance, which is similar to the mean square perturbation discussed later in

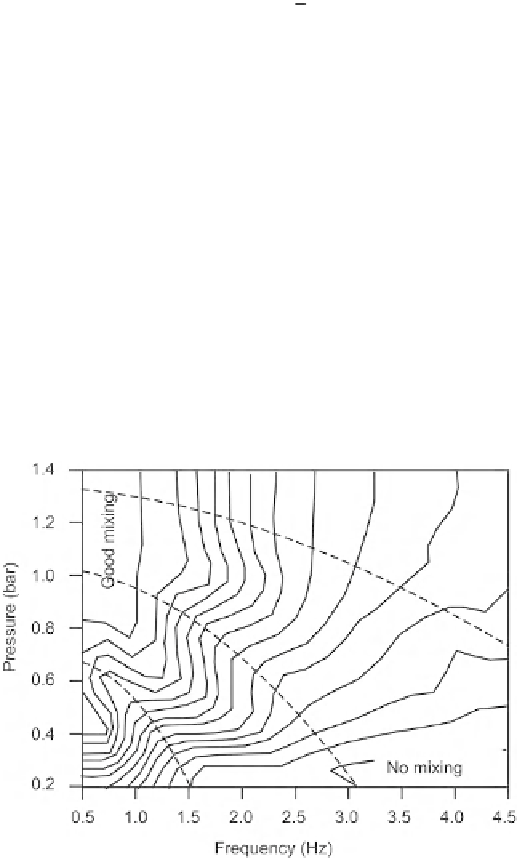

Chapter 8. A small variance means good mixing, while a large variance indicates bad mixing.

Figure 7.12

depicts the measurement results of this variance, which is comparable to the simulation

results shown in

Fig. 7.4

. At a fixed flow rate, good mixing can be achieved with a large disturbance

FIGURE 7.12

Mean square perturbation or variance in concentration as a function of magnitude and frequency of the

disturbance.

(Reprinted with permission from

[6]

.)

Search WWH ::

Custom Search