Biomedical Engineering Reference

In-Depth Information

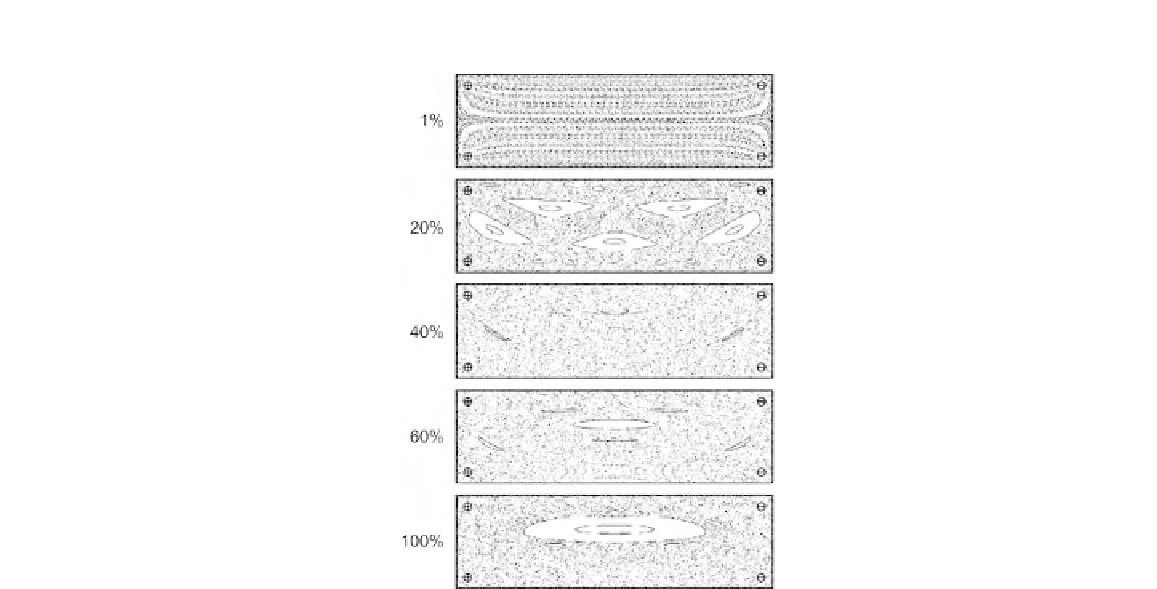

FIGURE 7.8

Poincar´ section of mixing with two source-sink pairs bounded by a rectangular mixing chamber at different

dimensionless switching time t

switch

.

(Reprinted with permission from

[9]

.)

a connecting microchannel. Integrated microheaters evaporates liquid water creating a vapor bubble,

which acts as the actuator. If the heat is removed, the bubble collapses due to condensation. A long

microchannel connects the actuation chamber with the pump chamber, which is located between the two

check valves. This long microchannel prevents the pumped liquid to be affected by the evaporation and

condensation processes in the actuation chamber. The microchannel network depicted in

Fig. 7.9

was

fabricated on a planar silicon substrate using deep reactive ion etching (DRIE) and silicon on isolator

(SOI) technology (see Chapter 4). The microheaters are made of polysilicon deposited on a quartz

substrate. The check valves are freely floating silicon structures. The silicon and quartz part are bonded by

adhesive bonding with an epoxy. Subsequent treatment with oxygen plasma free the epoxy blockage in

the microchannels.

Figure 7.10

shows another design of an active micromixer based on pressure-driven disturbance. In

contrast to the monolithic approach of Deshmukh et al., Fujii et al.

[11]

presented a hybrid approach,

where silicon micropumps are combined with a microchannel network in PDMS. Both the silicon part

and the PDMS part are bonded to a glass plate. Connecting holes are drilled in the glass plate that allow

liquids to be delivered from the pump to the mixing channel. The micromixer has the typical Y-design

with two inlets and a long mixing channel are molded in PDMS using soft lithography technique (see

Section 4.2.2.3). The silicon micropump is a valveless diaphragm pump driven by a piezoelectric

Search WWH ::

Custom Search