Biomedical Engineering Reference

In-Depth Information

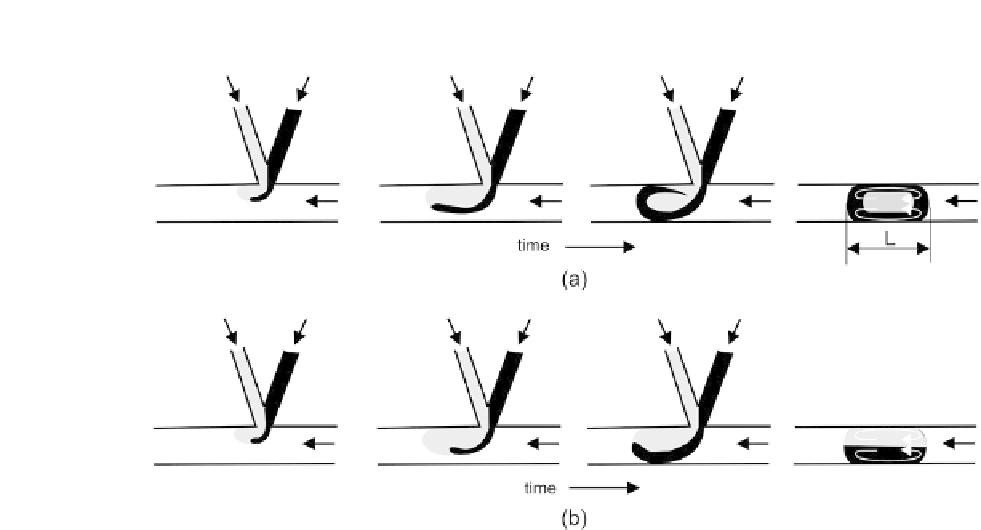

FIGURE 6.38

Droplet-based micromixer in a straight channel: (a) good initial distribution and (b) bad initial distribution.

distributed across both halves of the plugs and easily dispersed by the two internal vortices

(

Fig. 6.38

(a)). During the passage in the straight microchannel, the number of rotations is proportional

to the ratio between the traveling distance

x

and the plug length

L

. Thus, scaling of the mixing time can

be estimated as

t

mixing

f

L

=

x

:

(6.41)

If the velocity of the single vortex during formation is not high enough, the mixing liquid cannot

complete a 90

rotation. The mixing liquids are then separated in the two halves of the broken-up plug.

The liquids will stay in their halves because of the symmetric vortices. The mixing condition is then

similar to that of a simple T-mixer with parallel lamination (

Fig. 6.38

(b)).

As a rule of thumb, the initial distribution depicted in

Fig. 6.38

(a) can be achieved with a high shear

rate and a small plug. Thus, the higher the carrier flow rate and the smaller flow rate ratio

r

(see

(6.14)

),

the better the mixing in liquid plugs, which are formed and transported in a straight channel. Since the

internal velocity of the plug and the formation process itself are a complex interplay between flow

rates, viscosity, interfacial tension, and channel geometry, it is difficult to achieve the right initial

distribution in the plug. In the subsequent section, different schemes for achieving chaotic advection

inside the plug, when it is transported in a microchannel, are discussed. With chaotic advection, mixing

quality no longer depends on the initial distribution of the liquids.

6.4.2.2 Mixing based on chaotic advection inside a microdroplet

As mentioned previously, mixing in a microplug or a microdroplet moving in a straight channel relies

much on the initial distribution of the mixing liquids.

Figure 6.39

shows the mixing concept based on

Search WWH ::

Custom Search