Biomedical Engineering Reference

In-Depth Information

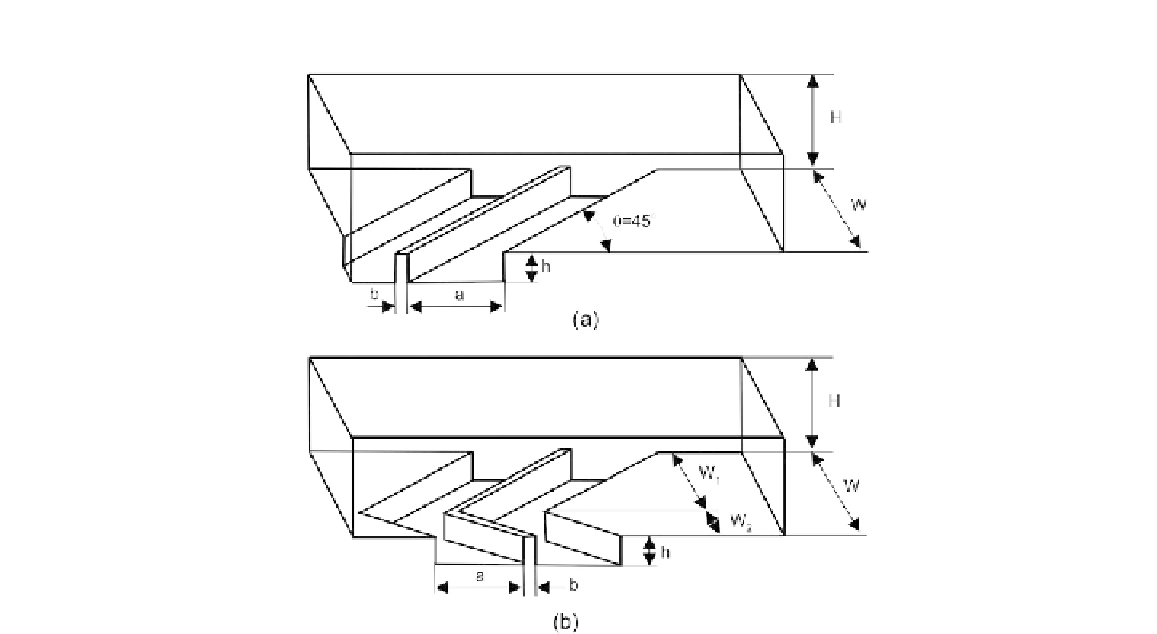

FIGURE 6.23

Geometrical parameters of (a) the SGM and (b) the SHM.

the lengths

a

and

b

of the groove and the ridge, respectively (

Fig. 6.23

). Since the asymptotic cases of

a

/

b

0 and

a

/

b

/

N

would lead to a Poiseuille flow with only axial flow component, there exists an

optimum for this ratio. Most of the reported works assumed a ratio of

a

/

b ¼

1. According to Lynn and

Dandy, at a ratio of the period

a þ b

and the channel width

W

of (

a þ b

)/

W¼

1, there is almost no change

when the ratio

a

/

b

is varied. The maximum variation is obtained with (

a þ b

)/

W¼

1/2. At this period/

channel width ratio, the optimum length ratio between the groove and the ridge is

a

/

b z

/

1/9.

A number of designs were derived from the two basic concepts discussed previously. Howell and

Floyd-Smith et al.

[33,34]

proposed a design with both types of ridges. Each mixing unit consists of

four slanted ridges at an angle of 45

and four symmetric (

p ¼

1/2) herringbone ridges. This design

aims to have alternate flow patterns with two vortices. As shown in

Fig. 6.24

, the structures on the top

wall and the bottom wall allow the formation of a pair of counter-rotating vortices vertically and

horizontally.

Fu et al.

[35]

proposed the designs of staggered oriented mixers (SORs) as depicted in

Fig. 6.25

.

The design only employs slanted structures on both top and bottom walls. The ridges on top and at the

bottom cross each other, allowing overlapping of the helical flows in the mixing channel. The

micromixer was fabricated on two glass slides. The ridges on both sides were wet-etched using an

aluminum mask. The glass slides are subsequently aligned and thermally bonded. Although the design

Search WWH ::

Custom Search