Biomedical Engineering Reference

In-Depth Information

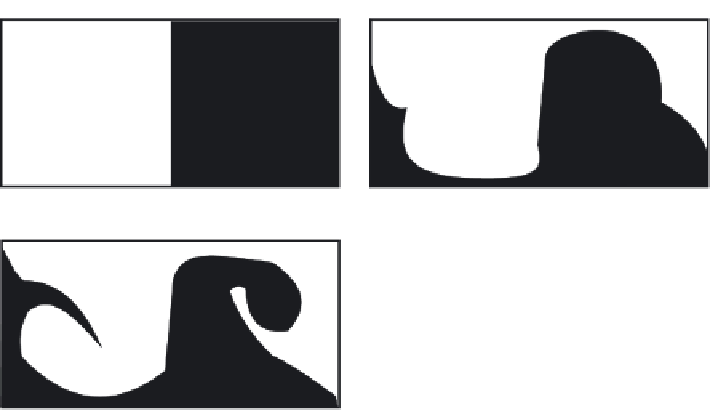

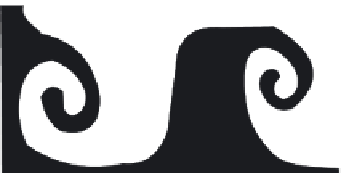

(a)

(b)

(c)

(d)

(e)

(f)

FIGURE 6.2

Concentration distribution at a dimensionless position of x

) ¼ 1.5: (a) Re ¼ 119; (b) Re ¼ 139; (c) Re ¼ 146;

(d) Re ¼ 153; (e) Re ¼ 159; and (f) Re ¼ 186 (after 2).

reactive ion etching. Sealing and optical access were made possible through anodic bonding to a glass

wafer. Mixing channels with depths less than 100

m were fabricated.

Kochmann et al.

[6]

presented further designs for mixing improvement at high Reynolds

numbers. Additional 90

turns are added after the T-junction. According to numerical simulation at

Re

¼

270

[6]

, a single 90

turn would reach a mixing efficiency (see Chapter 8) of 45%, while two

90

turns in the S-form and U-form (

Fig. 6.5

(a)) would allow the mixing efficiency to reach 65%

and 70%, respectively. In the tangential shear design depicted in

Fig. 6.5

(b), the T-junction inlet is

replaced by a shearing design. Instead of a head-on collision, the two mixing fluids enter the shear

chamber at different sides and leave it perpendicularly at the bottom. The micromixers were

fabricated in two layers of silicon. Microchannels were etched using DRIE technique. Optical

access was achieved with pyrex glass cover bonded anodically on top of the channel. The drawback

of the additional mixing elements is the increase in applied pressure, which is already too high for

the conventional T-mixer.

m

m and widths less than 200

m

Search WWH ::

Custom Search