Biomedical Engineering Reference

In-Depth Information

5.6.2

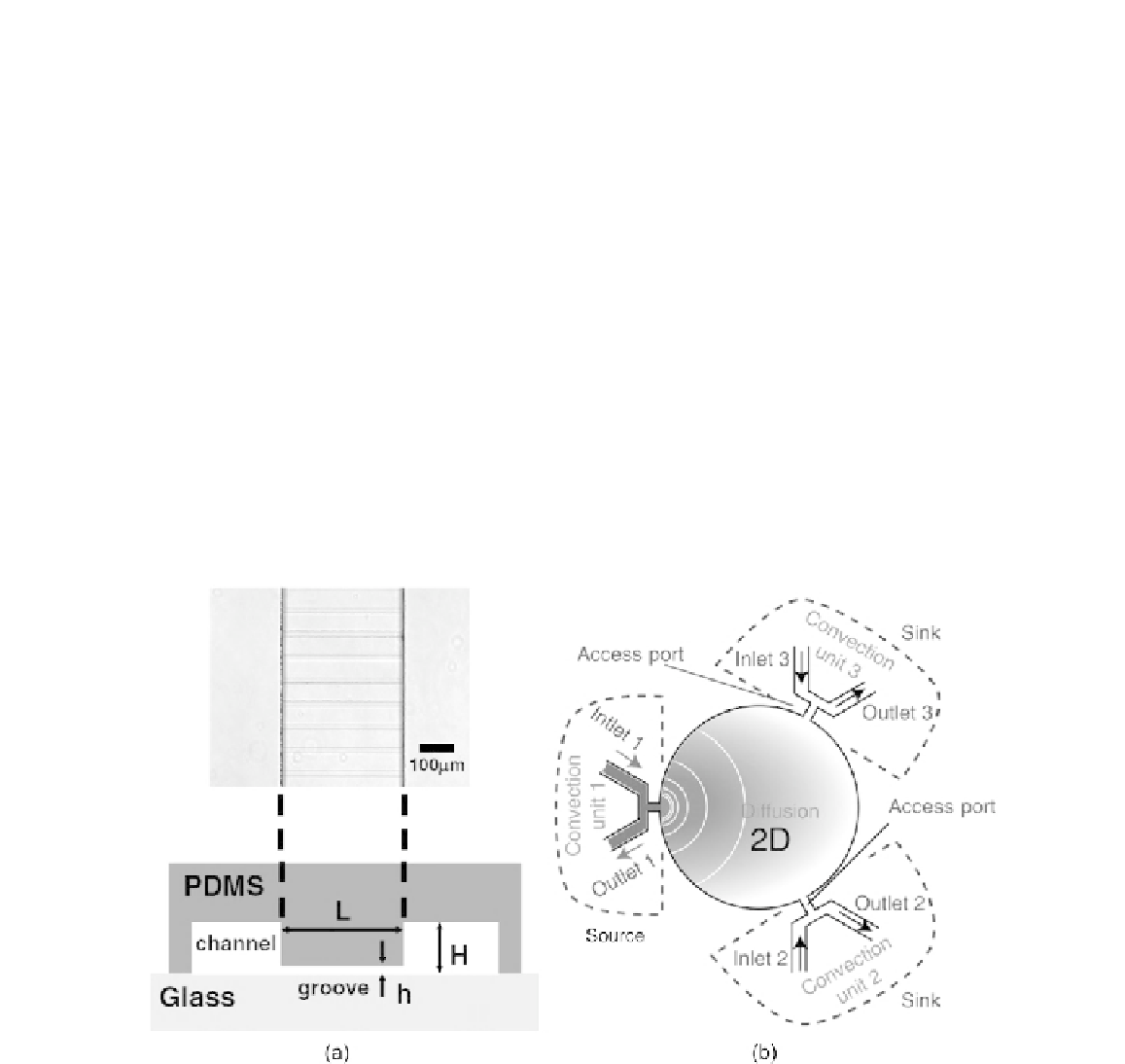

Free-diffusion gradient generator

Free-diffusion gradient generator forms the concentration field in a no-flow environment such as

microchannels with high fluidic resistance, porous membranes, or hydrogel. The concentration

gradient is formed by diffusion of the molecules between a source and a sink. Because of the slow

molecular diffusion process, free-diffusion gradient generators need a longer time to establish the

concentration field as compared to parallel lamination gradient generator.

Saadi et al.

[36]

formed a one-dimensional concentration gradient in a ladder-like microchannel

network. The source and sinks are two parallel microchannels, which are connected by an array of

microchannels with a much smaller depth (

Fig. 5.22

(a)). The high fluidic resistance of the micro-

channel array prevents the fluid to flow from the source to the sink and allows the gradient to build up

based on pure molecular diffusion. This gradient generator was successfully used for neutrophil

chemotaxis. Atencia et al.

[37]

developed a two-dimensional concentration gradient in a circular

chamber with three access ports working as sources and sinks (

Fig. 5.22

(b)). Switching the sources and

sinks allow the formation of a dynamic concentration field. A time of about 15 minutes is needed to

establish the concentration gradient in the chamber with a diameter of 1.5 mm.

Diao et al.

[38]

established the concentration gradient across a channel with porous nitrocellulose

membrane as side walls. Parallel microchannels work as the source and the sink. The disadvantage

of free-diffusion gradient generator is the fixed shape of the concentration distribution, which is

determined by the geometry of the gradient chamber and the boundary condition given by the sources

FIGURE 5.22

Free-diffusion gradient generator: (a) one-dimensional and (b) two-dimensional.

(Reprinted with permission from

[36]

and

[37]

.)

Search WWH ::

Custom Search