Biomedical Engineering Reference

In-Depth Information

Table 4.7

Properties of Common Polymers for Bulk Micromachining

r(kg/m

3

)

10

e

6

K

e

1

Materials

T

g

(

C)

k(W/K

m)

g

3

e

Parylene-N

410

1,100

0.13

69

Parylene-C

290

1,290

0.08

35

Parylene-D

380

1,418

—

30

80

e

Polyamide 6 (PA 6)

60

1,130

0.29

80

Polyamide 66 (PA 66)

70

1,140

0.23

80

Polycarbonate (PC)

150

1,200

0.21

65

Polymethylmethacrylate

(PMMA)

106

1,180

1,190

0.186

70

90

e

e

Polyimide

—

1,420

0.10

0.35

30

60

e

e

Polystyrene (PS)

80

100

1,050

0.18

70

e

( T

g

: Glass Transition Temperature,

r

: Density,

k

: Thermal Conductivity,

g

: Thermal Expansion Coefficient)

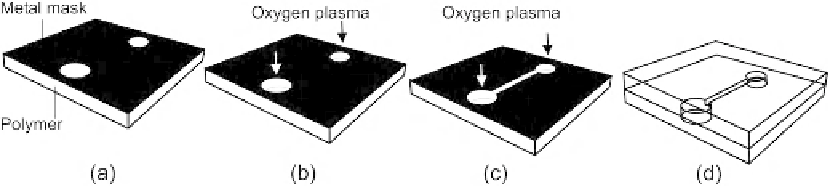

There are two key approaches in polymeric bulk micromachining: dry etching with oxygen plasma

and replication. Similar to silicon-based bulk micromachining, polymeric bulk micromachining uses

photolithography and etching to transfer a pattern into the bulk substrate. Oxygen plasma can be used

for etching polymers and other organic materials. Because photoresists are organic, a hard mask made

of metals such as aluminum, nickel, or titanium should be used here.

Figure 4.11

shows an example of

the fabrication of a microchannel with two access holes in a bulk polymeric material. To start with,

a metal layer is deposited on the polymer surface. Sputtering is preferred because a low temperature is

required for processing polymers. The metal layer is patterned and structured using conventional

lithography and etching techniques (

Fig. 4.11

(a)). The two access holes are first etched with oxygen

plasma (

Fig. 4.11

(b)). The metal layers are then etched to form the mask for the microchannel. Access

holes and microchannel etched until the areas of the access holes are opened on the backside of the

substrate (

Fig. 4.11

(c)). Finally, the mask is etched away and the microchannel can be sealed by

thermal bonding to another polymer sheet (

Fig. 4.11

(d)).

FIGURE 4.11

Fabrication of a microchannel with fluidic access holes: (a) Patterning the metal masks for the access holes;

(b) etching of access holes; (c) patterning the mask for the microchannel and etching until the access holes are

opened; (d) etching away the mask.

Search WWH ::

Custom Search