Biomedical Engineering Reference

In-Depth Information

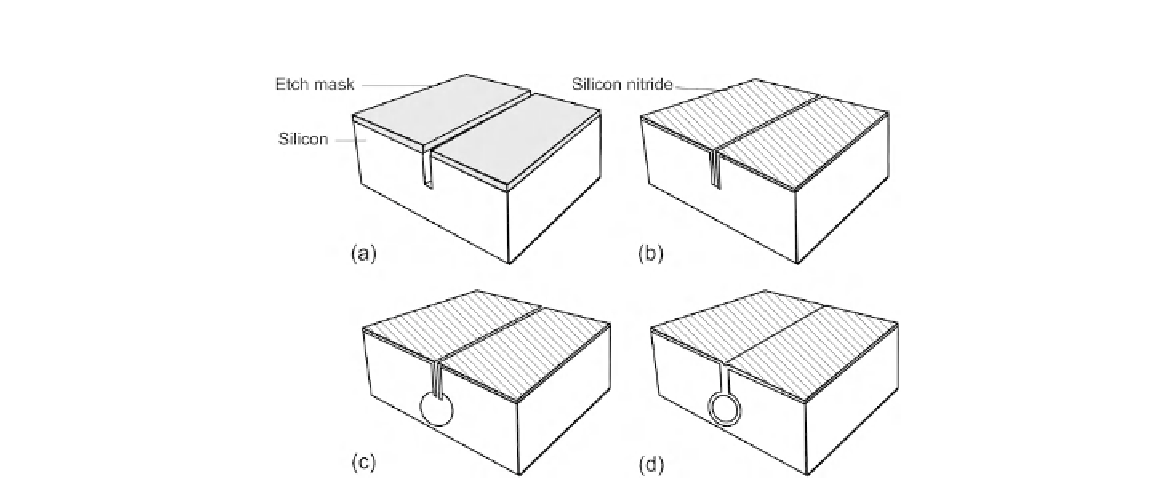

FIGURE 4.6

Buried channel with an arbitrary depth: (a) DRIE; (b) deposition of silicon nitride; (c) isotropic etching; and

(d) deposition of silicon nitride.

protecting layer, conformal LPCVD of silicon nitride seals the channel (

Fig. 4.6

(d)). The advantage of

this technique is that a network of channels can be fabricated at different depths in bulk silicon. Using

this technique, complicated designs, such as a three-dimensional conduit of a micromixer based on

chaotic advection, can be fabricated.

Because of the wavelengths on the order of few hundred nanometers, optical lithography cannot

create nanochannels with widths on the order of several tens of nanometers. Interferometric lithog-

raphy can be used for making structure size less than 100 nm. Some other techniques with high-energy

beams can also give a higher resolution. Direct writing with scanning electron beam lithography

creates structures with 10-nm resolution. However, the throughput of this technique is extremely low

due to its serial nature. X-ray lithography can deliver 50-nm resolution; however, such facility is

expensive and impractical for mass production. Another technique for making nanostructures is called

nanoimprint lithography or soft lithography. This technique uses a master, which is fabricated with the

more expensive technologies such as electron beam writing. Resist patterns can be transferred by

imprinting on a substrate surface. Open nanochannels can be fabricated by subsequent etching

processes. The nanochannels are covered with a deposition process.

4.1.2.4 Epi-micromachining or near-surface micromachining

Epi-micromachining or near-surface micromachining is a technology that allows fabricating micro-

structures in a thin layer of 2

10 micrometers on top of a silicon wafer. The general concept of epi-

micromachining is similar to that of polysilicon surface micromachining. Both need a sacrificial layer

beneath the functional layer. After structuring the functional layer and etching away the sacrificial

layer, a freestanding component can be released. Thus, having a sacrificial layer and ensuring the

selectivity to the functional layer are important for epi-micromachining.

e

Search WWH ::

Custom Search