Biomedical Engineering Reference

In-Depth Information

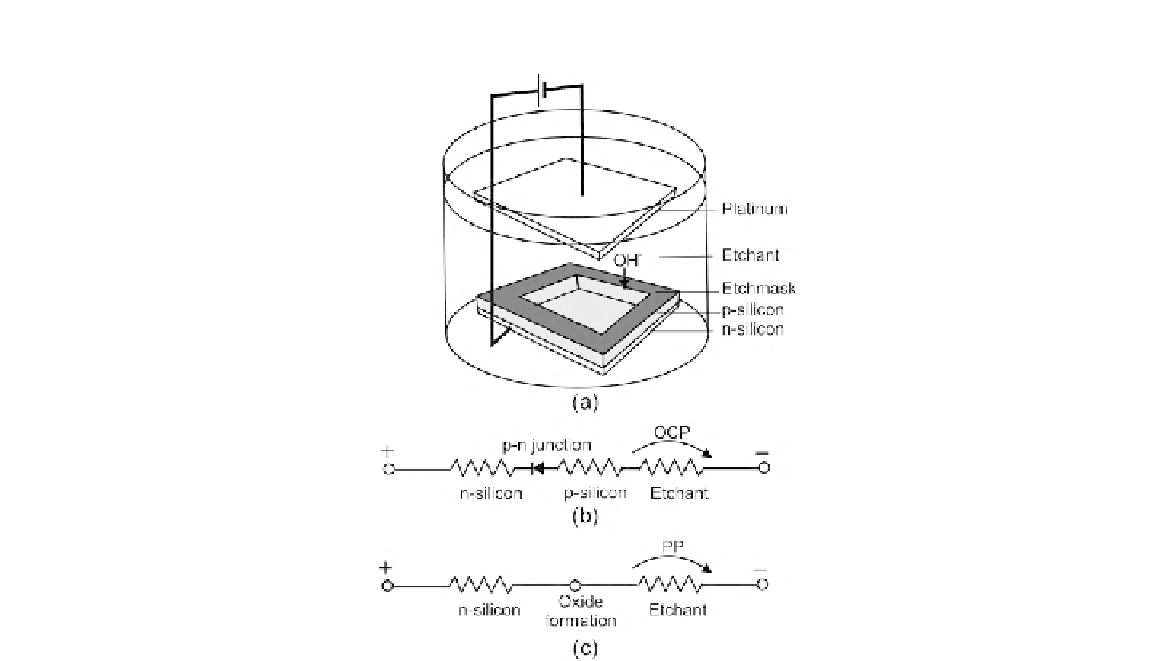

FIGURE 4.3

Electrochemical etch stop: (a) setup; (b) simplified circuit during etching; and (c) simplified circuit at etch stop.

drops to a PP value. The subsequent formation of silicon oxide on the surface automatically stops the

etching process as schematically depicted in

Fig. 4.3

(c).

A further approach of generating holes in silicon is photon pumping. Holes are generated in

positive bias n-silicon by illumination. This technique was utilized for fabricating high-aspect-ratio

structures

[18]

.

4.1.2.2 Dry etching

In dry etching, etchant gases or plasmas remove substrate materials. Generally, dry-etching

techniques are categorized as physical dry etching, chemical dry etching, and physical

chemical

e

etching.

Physical dry etching

utilizes the kinetic energy of particle beams, such as ion beam, electron beam,

or photon beam, to attack the substrate surface. The high-energy particles knock out substrate's atoms

from its surface. The knocked-out material immediately evaporates after leaving the substrate surface.

Since no chemical reaction is involved in this process, almost all materials can be removed by this

technique. The main drawbacks are slow etch rates, low selectivity, and trench effects caused by

reflected ions.

Search WWH ::

Custom Search