Biomedical Engineering Reference

In-Depth Information

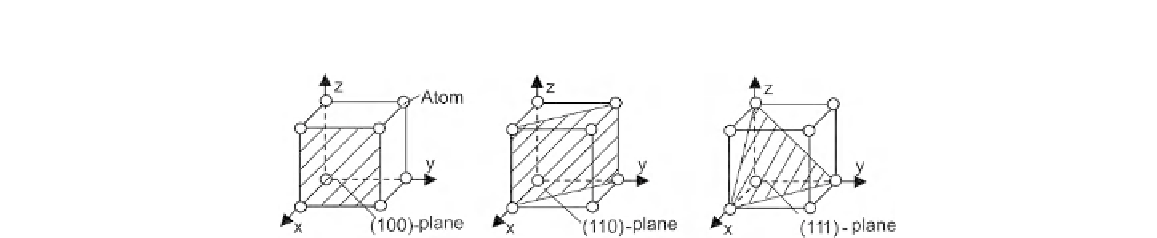

FIGURE 4.2

Different crystal planes in a cubic lattice of silicon atoms.

process due to evaporation and partly by subsequent baking at elevated temperatures. Spin coating

results in a relatively planar surface. This technique is often used for planarization purposes. Spin

coating can be used for the deposition of sol-gels. In this process, solid particles of a polymer

compound dissolved in a solvent are spin-coated on the substrate surface. The process forms

a gelatinous network on the substrate surface. Subsequent removal of the solvent solidifies the gel,

resulting in a solid film. This technique can be used for the deposition of various ceramics, such as lead

zirconate titanate (PZT). Besides spin coating, dry lamination, dip coating, spray coating, and elec-

trodeposition can be used for transferring a resist layer to the substrate surface.

4.1.2

Single-crystalline silicon

Because micromachining technologies have emerged from microelectronics, silicon remains as the

most important electrical and mechanical material for microsystems and microfluidics. The tech-

nology is established, and single-crystalline silicon wafers with high purity are commercially available

at a relatively low cost. In the early development, most micromixers were fabricated in silicon. In

general, silicon-based technologies are categorized as bulk silicon micromachining and silicon surface

micromachining. Bulk micromachining utilizes the single-crystalline silicon substrate as the device

material. Microchannels are etched directly into the silicon substrate. Surface micromachining can

utilize both single-crystalline and polycrystalline silicon as device materials. The single-crystalline

silicon wafer only acts as a carrier. Surface micromachining based on single-crystalline silicon is also

called epi-micromachining or near-surface micromachining.

Single-crystalline silicon wafers are classified by the crystalline orientation of their surfaces. The

classification is based on the

Miller indices

, which are shown in

Fig. 4.2

. A direction is described with

square brackets, such as

[100]

. Because of the symmetry, there are a number of [100]-directions. A set

of equivalent directions is described with angle brackets, such as

. If this direction is the normal

vector of a plane, the plane is denoted with parentheses such as (100). The set of equivalent planes is

described with braces, such as {100}. Single-crystalline silicon is mostly fabricated with the

Czo-

charalski method

(CZ method). This method starts with a small seed crystal, which determines the

orientation of the silicon substrate. The seed crystal is dipped into a highly purified silicon melt and

slowly pulled out of the melt, while the crucible containing the melt is rotated. Silicon crystals are

grown along the selected orientation of the seed to a rod.

Floating zone method

(FZ-method) is the

other method for fabricating silicon crystals. Instead of a silicon melt, a polysilicon rod is used as the

starting material. A seed crystal at the end of the rod defines the orientation. The polysilicon rod is

<

100

>

Search WWH ::

Custom Search