Biomedical Engineering Reference

In-Depth Information

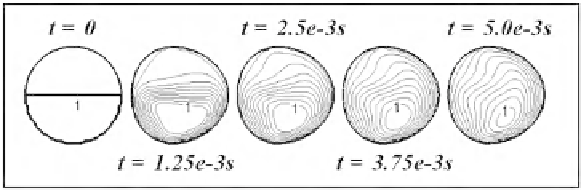

Figure 3.23

shows the concentration of species X in the droplet as it is carried by the flow. The

droplet deforms, although slightly, in the flow due to stresses exerted on it by the flowing oil.

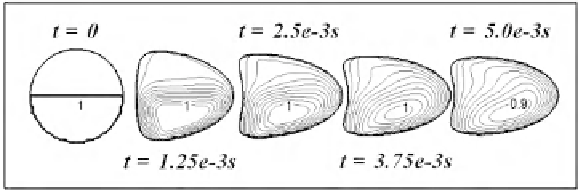

Figure 3.24

shows the case of a much lower surface tension of

s ¼

10

4

N/m. A lower surface

tension can be achieved physically, for example, by adding suitable surfactant. With a lower surface

tension, the deformation of the droplet is much larger. The deformation of the droplet by the flow

generates a larger

v

-velocity component. This helps mixing of species X within the droplet. The

highest concentration at

t

3.65

10

3

s is reduced from

c

¼

5.0

¼

1to

c

¼

0.9.

3.6.6

Mixing within a droplet flowing through a micro-U-bend

Figure 3.25

shows a water droplet carried by oil flowing in U-bend. The droplet of radius

R

1

¼

m is initially located at (50, 50). The lower half of the droplet contains a nonzero

concentration of species X(

c

35

m

1.0). There is no species X in the rest of the droplet. This problem is

governed by the same equations in Section

3.6.5

. The diffusion coefficient is again set to D

¼

10

8

¼

m

2

/s. The inlet velocity is specified as

u

o

¼

0.003 m/s. The evolutions of the droplet for

10

3

and

s ¼

10

4

N/m are shown in

Figs. 3.26 and 3.27

, respectively. For the

s ¼

3.65

3.65

10

4

N/m, the deformation of the droplet is large, especially when the droplet

negotiates the bend. The droplet breaks with a smaller satellite droplet formed trailing the main

droplet.

case of

s ¼

3.65

FIGURE 3.23

10

3

N/m.

Concentration of species X within a water droplet carried by oil for s ¼

3.65

FIGURE 3.24

10

4

N/m.

Concentration of species X within a water droplet carried by oil for s ¼

3.65

Search WWH ::

Custom Search