Biomedical Engineering Reference

In-Depth Information

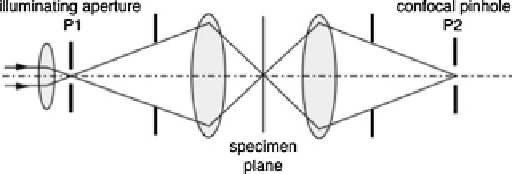

Fig. 6.8

Pinholes in the confocal microscope. P1 is a pinhole spatial filter, P2 is the confocal

pinhole

based mirrors and other scanning systems. Here a brief description of these laser

beam scanners is provided.

Galvanometric scanning is the most widely used scanning technology in

microscopy. This is due to its flexibility and price range. The principle of operation

of a galvanometer is identical to that of a motor in which the magnetic field produced

by an arrangement of permanent magnets is increased or decreased by the field from

a variable current electromagnet. The change in the field makes a magnet or an iron

to rotate. For slow scanning rates of a few frames per second, galvanometer scanning

is sufficient that has rms frequency of about 2 kHz. The scanners consist of a mirror

attached to a shaft that can rotate through a given angular range. Such scanners are

bandwidth limited, and therefore, it is not possible to exactly track an arbitrarily

specified position within the scan range [

12

]. With beam scanning, the light from

the sample must be descanned so that it does not move relative to the pinhole. This

is usually achieved by reflecting a second time from the galvo-mirror.

For video rate imaging, faster scanning of mirrors is required that can be

achieved by resonant scanners [

13

]. The main difference of a resonant scanner to

a galvanometer scanner is that the only moving part in the resonant scanner is a

single-turn coil, which reduces the damping in the scanning system and allows it

to be able to vibrate at very high frequencies, close to its mechanical resonance.

Since these scanners are designed to work close to resonant frequency, their angular

displacement can be very large. There are 10-kHz resonant scanners capable of 60 ˚

scan angles. Resonant scanners also cannot provide random access of points within

their scanning range. They are able to produce a sinusoidal scanning pattern at

frequencies as high as 12 kHz. In such scanners, in order to take advantage of the full

sinusoidal scan, data must be acquired in both the forward and backward directions.

In a polygonal scanning mirror system, very high frame rates can be obtained

[

14

,

15

]. In this scheme, the geometrical centre of a multifaceted polygonal mirror

is attached to a fast rotating shaft. As the motor rotates, the facets of the mirror will

scan the laser beam in a linear pattern. For slow scanning polygonal mirrors, ball

bearings are used in order to keep the price reasonable. At high rotation speeds

or larger mirrors, some problems might arise with precision bearings, such as

lubrication and vibration. Polygon mirrors can be noisy and produce air currents.

Search WWH ::

Custom Search