Biomedical Engineering Reference

In-Depth Information

Fig. 2.10

Schematic

configuration of the NW FET

transistor

NW

oxide

S

D

doped semiconductor = gate

immersion of

NWs in ethanol

uniform dispersion of

NWs in ethanol

sonication

pipette

deposition

Fig. 2.11

The deposition steps of NWs between NW FET contacts

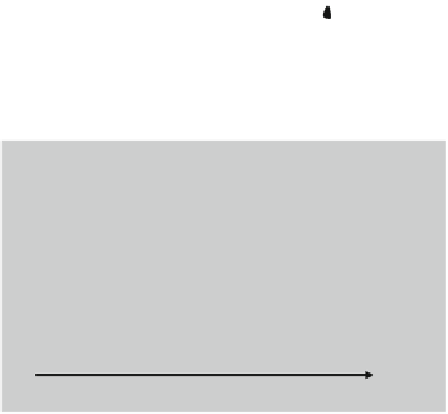

Fig. 2.12

The effect of

thermal annealing on the

source-drain I

D

-V

D

characteristic in a Si NW FET

I

D

(μA)

after thermal annealing

4

0

before

-4

V

D

(V)

-1

0

1

In general, the metal contacts of FETs based on NWs are of Schottky types,

and thus, the FET characteristics depend strongly on the contact properties. In Si

NW FETs, however, it was found that thermal annealing and passivation of oxide

defects enhance their performances, which become similar to those of Si MOSFETs

(

Cui et al. 2003

). Si NW FETs are produced using the steps illustrated in Fig.

2.11

,

followed by a 3-min thermal annealing process in hydrogen atmosphere at 600

ı

C.

As a consequence, the mobility and the transconductance of the FET increase 20

times (see Fig.

2.12

).

Many other technologies described in Chap.

1

can be used for the fabrication of

NW devices. For instance, electrodes for NW devices can be produced by room-

temperature nanoimprint lithography, which generates metal features on plastic

substrates. The NWs are deposited afterward on the plastic substrate using the

deposition steps in Fig.

2.11

. This method is used to fabricate many devices,

Search WWH ::

Custom Search