Biomedical Engineering Reference

In-Depth Information

a

b

c

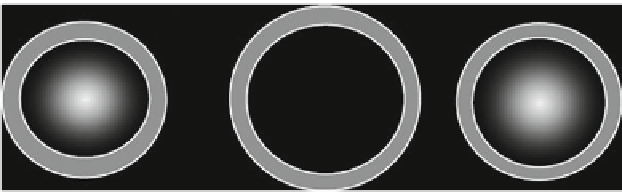

Fig. 8.7

Fabrication of a hemispherical electronic eye: (

a

) stretched hemispherical elastomer, (

b

)

array of detectors on the flattened elastomer, and (

c

) hemispherical electronic eye obtained after

releasing the elastomer

eye that has not only a three-dimensional refracting element but also a three-

dimensional arrangement of its detectors (

Ko et al. 2008

). This electronic eye is

illustrated in Fig.

8.7

. The hemispherical geometry, although suitable for a wide

field of view and low aberrations, is not compatible to the planar nanofabrication

techniques. Let us suppose that we want to fabricate a hemispherical eye camera

similar to the human eye, consisting of a number of pixels, the electronic part of each

pixel, referred to as silicon device, containing a photodiode and a blocking diode

monolithically integrated in a 500

500m

2

crystalline silicon and capped with a

micrometer thin polyimide layer. An ingenious trick is needed to place the silicon

devices manufactured using the usual wafer-scale two-dimensional technology on

a hemisphere: place first the two-dimensional array of Si devices on a flattened,

drumhead-like, radially stretched hemispherical elastomeric transfer element and

then release the elastomer to regain its hemispherical shape. The Si device array

adopts the same hemispherical shape due to van der Waals interactions with the

elastomer surface, but suffers no distortions if the interconnects between adjacent

Si devices are thin and narrow enough and have high elastic compressibility. In (

Ko

et al. 2008

), the interconnects were made from 50-m-wide, 360-m-long, and

3:150:3-nm-thick Cr:Au:Cr metal layers patterned on polyimide. These stages of

fabrication are illustrated in Fig.

8.7

. Afterward, the Si device array is transferred

onto a hemispherical glass substrate with the same radius of curvature and is

finally coated with a photocurable adhesive. Such a 16

16 pixels eye camera was

successfully fabricated and shown to function properly, and the poor image quality

due to the small number of pixels could be improved by collecting sequences of

images rotated in the azimuthal and polar directions by small increments and then

reconstructing the image (

Ko et al. 2008

); this strategy is also adopted in biological

systems.

In contrast to human and insect eyes, fish and octopus eyes use gradient index

biological structures to increase their focusing power and to correct spherical

aberrations. In particular, the octopus has no cornea so that it can see only with

the help of a spherical lens with an almost parabolic distribution of the refractive

index, obtained by a corresponding change of the water and protein concentrations.

Search WWH ::

Custom Search