Biomedical Engineering Reference

In-Depth Information

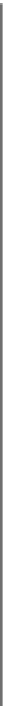

TABLE 12.2

Relative Cost of Biomass-Handling System

Capacity on as-Received Basis

100 Tons/Day

680 Tons/Day

System type

Manual

Automated

Truck tipper

11%

5%

Conveyor to wood pile

1%

Radial stacker, adder

4%

Front end loaders, adder

5%

Reclaim feeder

5%

Conveyor

3%

Metal separator

2%

1%

Screener

1%

5%

Grinder

12%

12%

Buffer storage

3%

5%

Fuel metering

12%

1%

Controls

5%

4%

Equipment installation

24%

5%

Civil/structural work

18%

1%

Electrical work

8%

4%

Total direct cost in 2003 dollars

$2,102,000

$4,857,000

Operating personnel required

5

4

Source: Prepared based on data from

www.epa.gov_chp_documents_chp_catalog_part4.pdf

.

design.

Table 12.2

gives an example of relative costs of different elements of

a typical biomass-handling plant. This table developed for biomass-fired

combined heat and power plant gives both relative capital cost of the

biomass-handling plant for a small 100 tons/day with manual loading of bio-

mass with front loader and for a 680 tons/day automated loading plant. The

manual plant requires a larger number of operating personnel. The unit cost

of dollar per ton per day is higher for lower cost and it is lower for larger

capacity unit. This analysis found the capital cost values as a function of

0.85 power (EPA, 2007) of the capacity of the plant.

capacity

0

:

85

Unit cost

(12.10)

B

Search WWH ::

Custom Search