Biomedical Engineering Reference

In-Depth Information

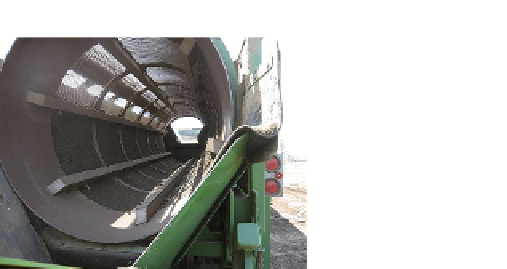

FIGURE 12.13

Portable trummel used in the fuel yard for size classification.

summer can reduce moisture by as much as 20% (Van Loo and Koppejan,

2008, p. 70).

The moisture in biomass must be reduced before use because it represents

a large drain on a plant's deliverable energy. Every kilogram of moisture

needs about 2300 kJ of heat to vaporize and an additional 1500 kJ to be

raised to a typical gasifier temperature of 700

C. This large amount of

energy (3800 kJ/kg) has to come from the energy released by the gasifier's

exothermic reactions. Therefore, lower moisture makes a higher amount of

heat available in the product gas.

Outdoor storage may not work well because of rain and snow, but precip-

itation can have a beneficial effect on some herbaceous biomass, such as

straw, since it leaches water-soluble agglomerates and corrosion-causing

elements such as chlorine and potassium. The three types of moisture in

a biomass gasifier are: (1) surface moisture, (2) chemical moisture, and

(3) moisture in air or steam used for gasification.

While the chemical (also called inherent) moisture cannot be reduced, it

is possible to reduce the surface moisture by drying, using the sensible heat

in the gasifier product gas, the flue gas of the combustor, or heat from other

external sources. A surface moisture less than 10

20% is desirable for most

gasifier types (Cummers and Brown, 2002).

The temperature of the hot gas used for drying the biomass is a critical

design parameter. Generally, it is in the range of 50

60

C. If much hotter

gas is used, it can heat the biomass above 100

C, and pyrolysis can set in on

the outer surface of the biomass before the heat reaches the interior. Besides

contributing to an energy loss though, such a hot gas can cause volatile

organic compounds to be released from the biomass that are potentially haz-

ardous. They are detected by a “blue haze” in the exhaust gas (Cummers and

Brown, 2002). The presence of excessive oxygen in the dryer can also lead

to ignition of fuel dust in the dryer, resulting in a potential explosion.

Therefore, oxygen concentration in the dryer should be kept below 10% to

avoid this risk (Brammer and Bridgwater, 1999).

Search WWH ::

Custom Search