Biomedical Engineering Reference

In-Depth Information

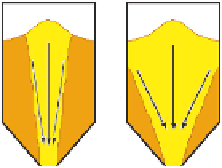

(A) No flow

(B) Mass flow

(C) Funnel flow

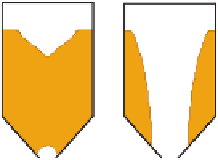

Arching

Ratholing

Stagnant material

Flowing material

FIGURE 12.6

Schematic representation of three types of solids flow through a hopper.

Mass flow (

Figure 12.6B

) is the preferred flow mode because here the

solids flow across the entire hopper cross section. Though there may be

some difference in velocity, this allows an uninterrupted and consistent flow

with very little radial size segregation, which permits the hopper to effec-

tively follow the first in first out norm. However, because of the solids'

plug-flow behavior, there can be more wear on the hopper walls with abra-

sive solids. Therefore, the required height of a mass-flow hopper must be

greater than that of a funnel-flow hopper. A steeper cone angle of a hopper

improves the probability of a “mass flow” mode of solids flow through it.

Some common operating problems with hoppers are:

Ratholing

Funnel flow

Arching

Flushing

Insufficient flow and incomplete emptying

Caking

Two of the most common problems experienced in an improperly

designed silo or bin (hereafter referred to as silo) are no-flow and erratic

flow. No-flow from a silo can be due to either arching or

ratholing

(

Figure 12.6A

).

Ratholing (

Figure 12.6A

, right) most often happens in the flow of bio-

mass with particles that are cohesive, have low shape factor, or rough surface

texture. This is a serious problem in hoppers. To facilitate solids flow, the

rat hole must be collapsed by proper aeration in the hopper or by vibrations

on the hopper wall.

Arching occurs when rough or cohesive particles form an obstruction

over the exit (

Figure 12.6A

, left), usually in the shape of an arch or a bridge

above the hopper outlet that prevents further discharge. The arch can be

Search WWH ::

Custom Search