Biomedical Engineering Reference

In-Depth Information

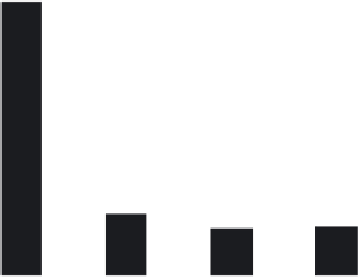

100

90

80

70

60

50

40

30

20

10

0

With CCS

2% biomass

5% biomass 10% biomass

FIGURE 10.1

Comparison of CO

2

capture cost by cofiring different percentage of biomass

with that of carbon capture and storage from a PC-fired boiler for biomass price $40 per dry ton.

Source: Plotted with data from Ortiz (2011), p. 61 and NETL (2010).

applicable to any plant as it was developed for one particular commercial

plant for one set of parameters, but it shows the relationship in a qualitative

term:

0044Z

2

Efficiency loss

0

:

0

:

0055Z%

(10.1)

5

1

10.3 EMISSION REDUCTION THROUGH BIOMASS COFIRING

Emissions of NO

x

,SO

2

, fly ash, and mercury from a coal-fired power plant

are of particular concern as they contribute to near-term local air pollution,

and as such their reduction is desirable. Biomass because of its inherent

property emits much less or none of these pollutants. Thus, cofiring could

bring a positive emission reduction from an existing power plant.

The ash content of biomass is generally much lower than that in coal

(

Table 10.1

). As a result, there is an overall reduction in fly ash production

with associated particulate reduction when some biomass replaces coal in a

power plant.

Biomass contains lesser amounts of nitrogen and sulfur than those in

coal. So, through cofiring, one could bring about a modest reduction in NO

x

and SO

2

emission. Many biomasses contain calcium, which is very effective

in absorbing the sulfur released from the coal during cofiring.

The higher volatile and higher hydrogen content of biomass could be

exploited in NO

x

reduction procedures such as air staging and reburning in a

cofired boiler. The improvement

in NO

x

reduction increases with the

Search WWH ::

Custom Search