Biomedical Engineering Reference

In-Depth Information

Entrained-flow gasifiers are essentially cocurrent plug-flow reactors,

where gas and fuel travel. The hydrodynamics is similar to that of the well-

known PC boiler, where the coal is ground in a pulverizing mill to sizes

below 75

m and then conveyed by part of the combustion air to a set of

burners suitably located around the furnace. The reactor geometry of the

entrained-flow gasifier is much different from the furnace geometry of a PC

boiler. Additionally, an entrained-flow gasifier works in a sub-stoichiometric

supply of oxygen, whereas a PC boiler requires excess oxygen.

The gasification temperature of an entrained-flow gasifier generally well

exceeds 1000

C. This allows production of a gas that is nearly tar-free and

has very low methane content. A properly designed and operated entrained-

flow gasifier can have a carbon conversion rate close to 100%. The product

gas, being very hot, must be cooled in downstream heat exchangers that pro-

duce the superheated steam required for gasification.

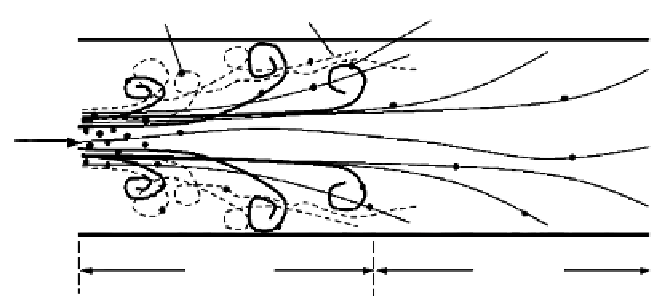

Figure 8.15

describes the working principle of an entrained-flow gasifier

by means of a simplified sketch. The high-velocity jet forms a recirculation

zone near the entry point. Fine fuel particles are rapidly heated by radiative

heat from the hot walls of the reactor chamber and from the hot gases down-

stream and start burning in excess oxygen. The bulk of the fuel is consumed

near the entrance zone through devolatilization; here, the temperature may

rise to as high as 2500

C.

The combustion reaction consumes nearly all of the oxygen feed, so the

residual char undergoes gasification reactions in CO

2

and H

2

O environments

downstream of this zone. These reactions are relatively slow compared to the

devolatilization reaction, so the char takes much longer to complete its con-

version to gases. For this reason, a large reactor length is required.

Entrained-flow gasifier design may be classified into two broad groups:

(i) the top-fed downflow (used by GE Energy and Siemens SFG), shown in

μ

Gas particle

Fuel particle

Fuel particle path

Pulverized

fuel + O

2

(

Combustion

zone

Gasification

zone

Fuel particle path

Gas path

FIGURE 8.15

Simplified sketch of gas

solid flow in an entrained-flow gasifier.

Search WWH ::

Custom Search