Biomedical Engineering Reference

In-Depth Information

To syngas cooler

Gas-Solid

disengager

Cyclone

Riser gasifier

Maxing zone

Loopscal

Feed

Air

Steam

Standpipe

Air, Oxygen, Steam

J-Value

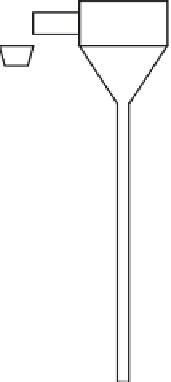

FIGURE 8.11

A sketch of a typical transport fluidized-bed gasifier.

exothermic combustion reaction necessary for a self-sustained gasifier. To

avoid the dilution, oxygen could be used instead, but oxygen gasification

is expensive and highly energy intensive (see Example 8.5). A twin reactor

(e.g., a dual fluidized bed) overcomes this problem by separating the combus-

tion reactor from the gasification reactor such that the nitrogen released in the

air combustion does not dilute the product gas. Twin reactor systems are used

for coal and biomass. They are either externally or internally circulating.

This type of system has some limitations; for example, Corella et al.

(2007) identified two major design issues with the twin or dual fluidized-bed

system:

1. Biomass contains less char than coal contains; however, if this char is

used for gasification, the amount of char available may not be sufficient

to provide the required endothermic heat to the gasifier reactor to main-

tain a temperature above 900

C. This external heating may be necessary.

2. Though the gasifier runs on steam, only a small fraction (

,

10%) of the

steam participates in the gasification reaction; the rest of it simply leaves

the gasifier, consuming a large amount of heat and diluting the product gas.

The Technical University of Vienna used an externally circulating system

to gasify various types of biomass in an industrial plant in Gussing, Austria.

The system is comprised of a bubbling fluidized-bed gasifier and a CFB

combustor (

Figure 8.12

). The riser in a CFB that is fluidized by air operates

Search WWH ::

Custom Search