Biomedical Engineering Reference

In-Depth Information

Biomass

20 C

Drying

100 C

500-700 C

Pyrolysis

Air

Air

Combustion

1000-1400 C

Gasification

Temperature (C)

Gas

Gas

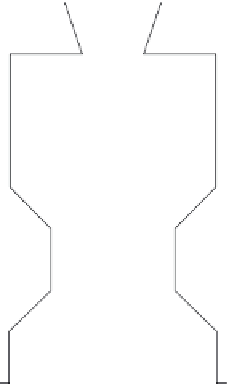

FIGURE 6.4

Tar generation is downdraft gasifier. The tar produced passes through the highest

temperature zone in a downdraft gasifier, and as such it is easily cracked.

6.3.1.3 Tar Reduction by Catalysts in Fluidized-Bed Gasifiers

Catalysts accelerate the two main chemical reactions of tar reduction. In a

steam-reforming reaction, we have

Catalyst

C

n

H

x

1

nH

2

O

!

ð

n

x

=

2

Þ

H

2

1

nCO

(6.5)

1

In a dry-reforming reaction, we have

Catalyst

nCO

2

!

ð

=

Þ

2nCO (6.6)

Catalysts can facilitate tar reduction reactions either in the primary reac-

tor (gasifier) or downstream in a secondary reactor. Three main types of cat-

alysts used are dolomite, alkali metal, and nickel. Olivine, and char have

also found successful use as catalysts for tar reduction. Effects of these cata-

lysts are detailed below.

C

n

H

x

1

x

2

H

2

1

Dolomite

Dolomite (MgCO

3

, CaCO

3

) is relatively inexpensive and is readily available.

It is more active if calcined and used downstream in the postgasification sec-

ondary reactor at above 800

C (Sutton et al., 2001). The reforming reaction

of tar on a dolomite surface occurs at a higher rate with CO

2

(

Eq. (6.6)

) than

with steam (

Eq. (6.5)

). Under proper conditions, it can entirely convert the

tar but cannot convert methane if that is to be avoided for syngas production.

Search WWH ::

Custom Search