Biomedical Engineering Reference

In-Depth Information

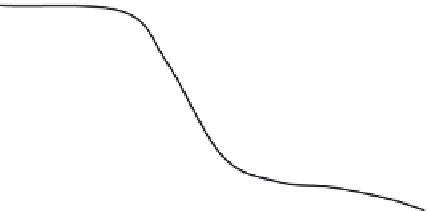

(A)

100

75

50

25

0

100

200

300

400

500

Temperature (°C)

Hemicellulose

Cellulose

Lignin

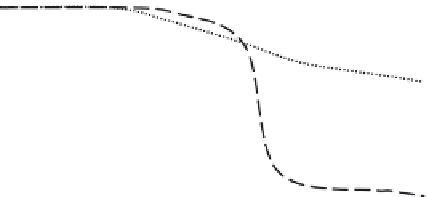

(B)

500

400

300

200

100

0 5 0

Hemicellulose (%)

0 5 0

Cellulose (%)

0 5 0

Lignin (%)

0 5 0 5 0

Total yield (%)

FIGURE 4.5

(A) A comparison of degradation of lignin, cellulose, and hemicellulose in inert atmo-

sphere. Lignin represents acid lignin. (B) A qualitative diagram of mass loss of torrefaction of different

polymeric

(initial

composition of yellow poplar: hemicellulose

16.6%,

cellulose

42.2%,

5

5

lignin

25.6%). Source: (A) Drawn from the experiment of Shafidazeh and McGinnis (1971)

with cottonwood in a TGA.

5

4.4.3 Effect of Design Parameters on Torrefaction

The following section discusses how some feed and operating parameters

influence the torrefaction process.

4.4.3.1 Temperature

Torrefaction temperature has the greatest influence on torrefaction as the

degree of thermal degradation of biomass depends primarily on the tempera-

ture.

Figure 4.6A

illustrates this effect showing how the mass yield decreases

with increasing temperature.

Figure 4.6B

shows that energy yield also

decreases with increasing temperature. Higher temperature gives lower mass

and energy yields but higher energy density. The fraction of fixed carbon in

a sample increases while that of hydrogen and oxygen decreases as the torre-

faction temperature increases (Bridgeman et al., 2008). Cielkosz and

Wallace (2011) observed that mass yield variation is related to the tempera-

ture, T

t

, and residence time, t, by an exponential function of (t/T

t

).

Search WWH ::

Custom Search