Biomedical Engineering Reference

In-Depth Information

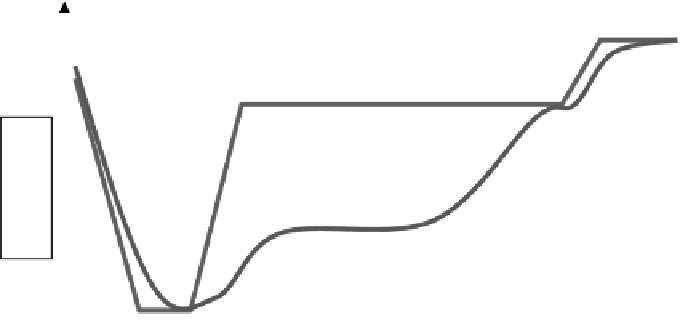

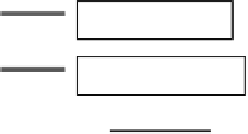

Freeze drying cycle

Secondary

drying

Freezing

Primary drying

Time (h)

Shelf temperature

Product temperature

Figure

13.8.

Genericized freeze-drying cycle.

attributes [40]. Key aspects of the lyophilization cycle (Fig. 13.8) must include

maintaining the product temperature below its collapse temperature T

c

during freeze-

drying, which is the temperature at which freeze-dried cake will collapse. The primary

drying phase of the process (sublimation of ice under vacuum) is the longest step, but must

be optimized to be as short as possible, as this adds time and cost to the process.

The secondary drying phase (desorption of water from the product under high vacuum

and high product temperature) must not start until the primary drying is completed, as this

may take the product temperature above T

c

during primary drying.

The application of PAT tools in freeze-drying covers a verywide range of usage. One

of the reasons for this is that the full operating conditions of the full-scale commercial

manufacturing freeze-dryer can be duplicated easily in off-the-shelf scaled-down free-

ze-dryers and the physical conditions of cooling and heating, reduced pressure under

vacuum, and purging with inert gases can all be executed in model systems directly

linked to PAT-like tools [41].

13.5.8 Freezing

Freezing has been studied extensively to understand ice formation, crystallization, and

amorphous state of API and excipients. The rate of freezing can influence ice formation,