Biomedical Engineering Reference

In-Depth Information

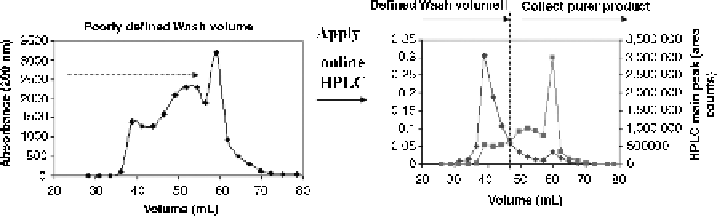

Figure

12.5. Online reverse-phase HPLC for ion exchange fraction pooling to monitor removal

of low molecular weight impurity.

demonstrate that the ability to use the data from the reverse-phase separation to define the

wash volume based on removal of low molecular weight impurity instead of a

predetermined number of column volumes (CVs) used in the wash step (Fig. 12.5).

In a separate set of experiments, Lanan, Kiistala, and Parikh [38] demonstrated the

ability to monitor a protein pegylation reaction to completion by size exclusion

chromatography. A column switching valve was placed between a sampling probe

outlet line from stainless steel pegylation reactor vessel and the analytical HPLC. A

peristaltic pump was used to draw sample from the vessel into the HPLC tubing into the

sample loop on the rheodyne injector valve. The sample loop was switched in-line at

predetermined periodic intervals and a size-based separation was performed from the

beginning of the pegylation reaction to completion. Visualization of the protein of

interest, the monopeglyated species of the protein, and the multipegylated species of the

protein can be achieved by plotting stacking the chromatograms from earlier sampling

points on top of chromatograms from later sampling points (Fig. 12.6a).

By plotting all peak areas from the multi-PEG, mono-PEG, and the raw material

PEG, Lanan, et al. were able to visualize a real-time assessment for the completion of

reaction. With the batch of polyethylene glycol used in this experiment, pegylation of the

protein was complete in approximately 10 h (Fig. 12.6b). This specific application of a

PAT tool would allow the process decision to be made on the basis of an “end point”

analysis, rather than a set time period. If rawmaterial variability in such reactions were a

concern, then having a window into the process might be considered advantageous, as it

would lead to the same product quality regardless of the raw material variability.

In addition, flow injection analysis (FIA) is making a comeback as a PAT tool for

purification. Almeida et al. [45] used FIA to demonstrate the ability to make Fusarium

solani pisi cutinase assessments from an expanded bed absorption eluate using micro-

encapsulation of p-nitrophenylbutyrate (p-NPB) in a micellar system. They were able to

distinguish slight differences in yeast cultivation conditions during cutinase production

that influenced the fermentation performance that affected the adsorption of cutinase

during resin loading. They demonstrated a good correlation between the FIA system

results and the off-line cutinase activity results. Putting this type of system in-line and

using either principles of hydrodynamic chromatography or field flow fractionation may

allow process engineers to assess purification fractions based on larger molecular weight

heterogeneity without the addition of a stationary phase. This approach would also solve