Biomedical Engineering Reference

In-Depth Information

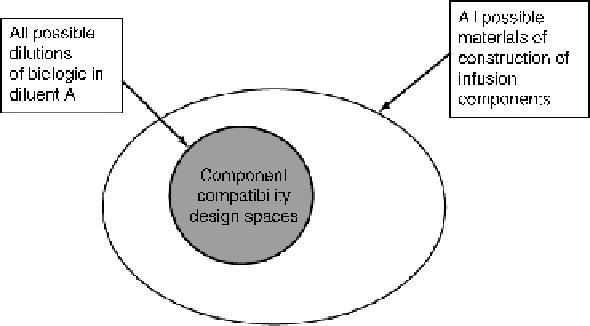

Figure

10.9.

A schematic illustration of the component compatibility design space for an

infusion product.

An important component of the above compatibility requirement is the qualification

of various infusion components for use with the biologic product. For a product to be

marketed worldwide, it is obvious that a large number of component manufacturers

would be in question. Since it is not possible to qualify all potential components for a

variety of manufacturers, a bracketing strategy based on DOE was applied. The strategy

based on qualifying materials of construction instead of specific components makes the

results applicable to components other than those tested. The elements tested in the DOE

are listed in Table 10.7, along with the actual design in Fig. 10.8.

The study showed the compatibility of the biologic with the materials of

construction of the most commonly used infusion components and the concentration

range within which the compatibility existed, thus defining a design space in which

the biologic could be used. This is illustrated schematically in Fig. 10.9.

10.4 CONCLUSIONS

A systematic work process has been defined to apply risk-based approaches to generate

process understanding and align ICHQ8, Q9, and Q10. The examples provided illustrate

the many ways in which the concepts of QbD and design space can be applied to biologic

product—formulation and process development.

REFERENCES

[1] Carpenter JF, Pikal MJ, Chang BS, Randolph TW. Rational design of stable lyophilized

protein formulations: some practical advice. Pharm Res 1997;14:969-975.

[2] Patro SY, Freund E, Chang BS. Protein formulation and fill-finish operations. Biotechnol

Ann Rev 2002;8:55-84.