Biomedical Engineering Reference

In-Depth Information

TABL E 9.4. (

Continued

)

Factors

Selection Rationale

Excipient such as surfactant

stabilizer is selected to effectively

minimize physical instability

issues. The optimal level of

excipients can be determined by

DOE results summarized in the

context of formulation design space

Tonicity agent is selected based on

preformulation and formulation

DOE results with better chemical

and physical stability properties

prototype stability results are compared to the statistical model prediction to update and

finalize the stability risk assessment.

9.10

SUMMARY

The design of a commercial formulation composition in accordance with the Quality by

Design principles generally involves the following steps:

.

Identification of target commercial drug product profile.

.

Preformulation and forced degradation studies to characterize molecular stability

properties, impact of formulation variables, and other factors.

.

Preliminary stability risk assessment with emphasis on direct impact on the

activity based on preformulation and forced degradation studies results.

.

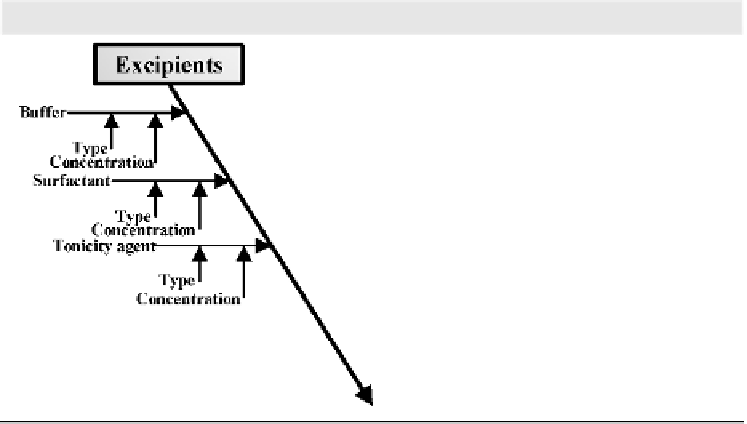

Initial formulation risk assessment to establish the cause-effect relationship of

different factors and solution formulation stability via the Ishikawa (Fishbone)

diagram.

.

Multivariate DOE studies to optimize the formulation composition and define a

robust design space to meet the expected shelf life of 24 months at 5

C.

.

Establish formulation design space based on DOE results and stability properties

projections.

Select commercial solution formulation based on design space, molecule knowl-

edge, and risk assessment.

.