Biomedical Engineering Reference

In-Depth Information

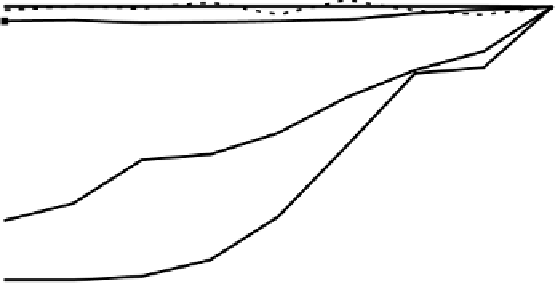

120.00

100.00

80.00

60.00

mAb1 % yield

Main charge isoform

% Monomeric mAb1

CHOP

DNA

40.00

20.00

0.00

4

4.25

4.75

5

5.25

5.5

6

6.5

6.8

Harvest pH

Figure

7.2.

Effect of harvest pH on product attributes and the level of CHO host-cell impurities

after centrifugation. The

-axis represents the levels of product and impurities in the centrate,

normalized to the pH 6.8 harvest condition. Adjustment of the cell culture harvest medium to

acidic pH causes cells to flocculate, resulting in more efficient centrifugation. In addition, the

pH-inducedflocculation results in reduced levels of CHOhost-cell protein (CHOP) andDNA in the

centrate. Harvest at reduced pH did not alter the product (mAb1) recovery, charge profile, or

level of aggregation.

y

the product concentration in the centrate or product quality attributes such as aggregation

and charge variants.

These findings indicate that harvest pH affects the purity of the load onto the rPA

capture column and the harvest-capture design space was explored together in a series of

DOEs. Other centrifugation parameters (e.g., g-force and flow rate) did not significantly

alter the properties of the filtered centrate (rPA column load) across relatively wide

ranges of operation. These parameters were not a significant source of process variation

and offered little or no opportunity for process control. Thus, these “nonkey” parameters

were not included in the subsequent design space studies. As mentioned earlier, product

recovery and product attributes are relatively insensitive to the harvest pH. In addition,

DNA is easily removed by the rPA and subsequent chromatography steps. Thus, the

primary response for the DOE studies was determined to be the clearance of CHOP. The

sequence of these experiments is summarized in Table 7.2. Briefly, of the 19 input

parameters identified for the operation of the rPA capture column, 7 were identified as

nonkey parameters based on prior process knowledge and were not carried forward into

the resolution IV screening design. Of the 12 parameters tested in the screening DOE, 4

were shown to have significant effects on the process or the product and carried forward

into the subsequent modeling design. The experimental design matrix for the modeling

DOE is shown in Table 7.3. For this exercisewith four input variables, a D-optimal design

comprising 32 chromatographic runs carried out in two blocks was selected. This

orthogonal response surface design (power

>

80 and 95% confidence interval) was