Biomedical Engineering Reference

In-Depth Information

(a)

Scaled estimate

Prob>|t|

Lower 95%

Upper 95%

Term

112.47703

40.388217

19.587127

24.58929

-27.27513

<.0001*

<.0001*

0.0032*

<.0001*

0.0004*

106.84443

23.915839

6.6933673

13.249103

-42.1284

118.10963

56.860596

32.480887

35.929477

-12.42186

Intercept

pH (growth)

DO%

Temperature (growth)

Feed-1 rate

(b)

200

150

100

50

0

-

-

-

+

+

+

Temperature

(growth)

pH (growth)

DO%

Feed-1 rate

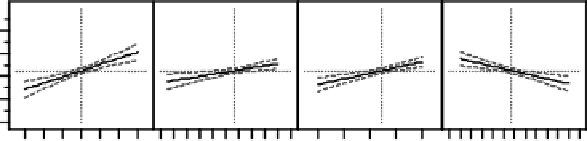

Figure

5.14.

Building a regression model for product quality 1 based on the acceptable

operating ranges. Note: Data have been normalized against the average small-scale model

performance at set point operating conditions. The symbols

and

þ

indicate the low and high

end of the operating range, respectively.

Next, a Monte Carlo simulation was performed in which the ranges of statistically

significant operating parameters were varied either triangular or uniformly within the

acceptable operating ranges (Fig. 5.15a). A triangular distribution for the Feed-1

parameter was selected to better represent the expected operational variation and control

tolerance around the target SP. Random noise was applied during the simulation that is

derived from the root mean square error associated with the model prediction. Fourth,

two-sided tolerance intervals were calculated based on the simulated performance data

(n

10,000) calculated to contain 99% of the population with 95% confidence

(Fig. 5.15b). The calculated performance output adhered to a normal distribution. For

generation of the initial model, all possible conditions (including interaction of multiple

operational parameters within the acceptable operating range) were considered with

equal weight or chance of occurrence. TheMonte Carlo simulation appropriately assigns

a higher probability to runs performed at SP of the operating ranges and lower probability

to runs performed at the edges of the ranges.

The PVAC calculated by Monte Carlo simulation are presented in Fig. 5.16.

They represent the tolerance interval describing 99% of the future data with 95%

confidence. As shown, the process performance at SP operating conditions falls well

within the PVAC. In addition, the observation that the worst and best case experiments

within normal operating conditions fall alsowithin the PVAC for product quality 1 further

demonstrates the robustness of the process. It should be pointed out that data from the

growth PC study that exceed PVAC were from experiments performed under extreme

conditions. These resulted in unacceptably high product quality 1 levels and thus, they are

expected to fall outside the proposed process validation acceptance criteria.

¼