Biomedical Engineering Reference

In-Depth Information

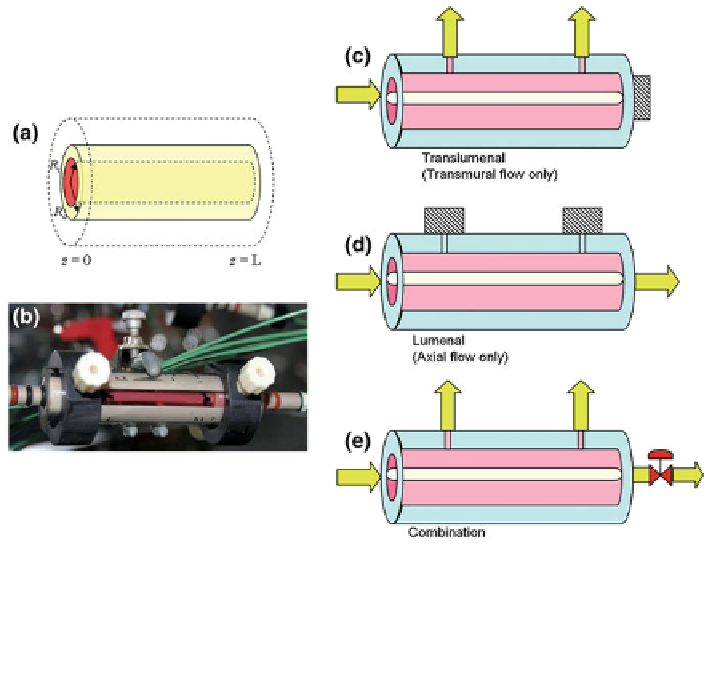

Fig. 3 Bioreactor configurations analyzed for steady flow. a Illustration of tissue dimensions

within the bioreactor. b Photo of the bioreactor in operation. Schematic of c translumenal flow

(axial outlet blocked), b lumenal (translumenal outlets blocked) and c combination of

translumenal and lumenal flow. Flow proceeds from the inlet on the left side, then either

through the tissue to outlet ports on the side (c, e) or axially out from the tubular tissue construct

(d, e)

fibrin-based tubular tissue constructs, in order to monitor oxygen consumption of

the tissue and provide data for DO model development. The model in this case was

expanded to include axial and transmural flow and was coupled to the DO

transport model using COMSOL. The model predicted DO profiles across the

tissue thickness as a function of the transmural flow rate as well as shear rates on

the cells within the tissue and the potential for construct bursting associated with

pressures required to impart a prescribed transmural flow.

Multiple bioreactor configurations were implemented by blocking chamber exit

ports as shown in Fig.

3

. Pure transmural (''translumenal'') flow was obtained by

blocking the axial outflow port, pure axial (''lumenal'') flow by blocking both

transmural exit ports, and simultaneous transmural and axial (''combination'') flow

were implemented by incorporating both transmural exit ports and the axial exit

port. In addition, the transmural flow rate was adjusted in this configuration by

utilizing a pressure transducer and needle valve downstream of the axial exit port.

The needle valve was adjusted to achieve a desired lumenal pressure which

corresponded to a transmural flow velocity, v

r

, given by Darcy's Law:

Search WWH ::

Custom Search