Biomedical Engineering Reference

In-Depth Information

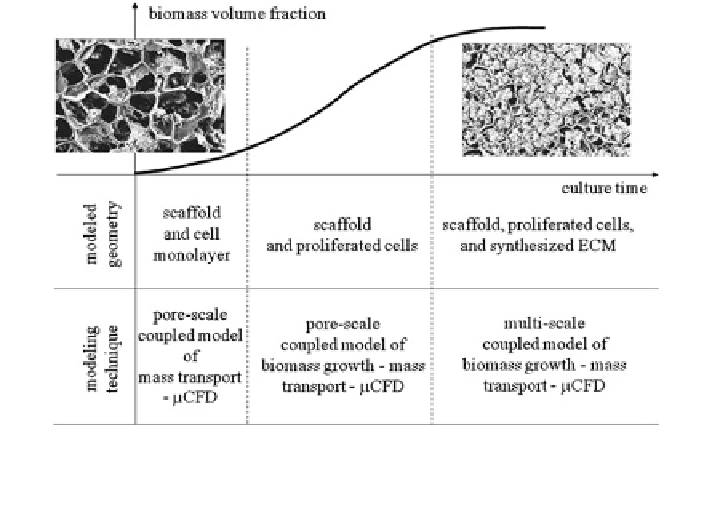

Fig. 4 Hierarchy of computational modelling techniques for cartilage tissue growth, following

the evolution of the geometry of the cell environment upon culture time. A coloured version of

this figure is available on the online version of the topic

3 Coupled Models of Medium Flow and Mass Transport

A rough understanding of transport limitations in porous constructs has been

obtained, in absence of flow, by Botchwey et al. [

2

,

3

] and Sengers et al. [

45

] using

homogeneous models of tissue-engineered constructs. This amounts to solving

Eq. (

1

) with a constant nutrient diffusivity and v = 0 in the entire scaffold domain X,

instead of considering the actual microscopic structure of the domain X

e

with its

associated complex empty and filled substructures. In up-to-date recent tissue

engineering bioreactors, the cell-seeded scaffold is immersed in a medium which is

induced to flow through or around the scaffold surface in a perfusion flow apparatus.

A simple strategy for increasing mass transport to cells would appear to be to increase

the medium flow rate, but high flow rates induce high shear stresses on cells, which

may be harmful instead of beneficial, at least at early stages of tissue growth.

This complexity presents serious hurdles in determining the appropriate values

of flow rate and medium solute concentration. Flow around scaffolds in a con-

centric cylinder bioreactor has been studied by Williams et al. [

49

] by solving

Eq. (

2

) coupled with Eq. (

1

) in the whole bioreactor domain. In this model, the

biomass volume is not accounted for in the geometry, but an equivalent volumetric

consumption rate is used at the right-hand side of Eq. (

1

). Such a model allowed to

compute flow fields, shear stresses and oxygen profiles around the constructs.

Incorporating flow through the scaffold in a direct-perfusion configuration

complicates the situation by establishing a velocity scale which is related to the

Search WWH ::

Custom Search