Biomedical Engineering Reference

In-Depth Information

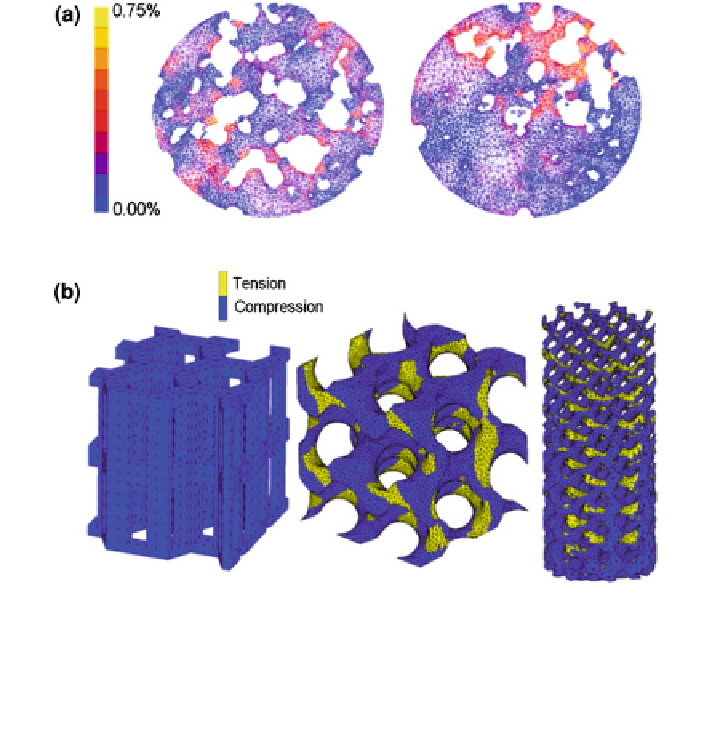

Fig. 3 a Examples of distribution of octahedral shear strain in two samples for CaP cement (left)

and glass (right) scaffold morphologies (modified from Lacroix et al. [

9

]). b Major strain

distribution in RP pores; the zones under tension or compression strain are delimited; prism

hexagonal shape with 70% of porosity (left), gyroid pore structure with 70% of porosity (middle),

and gyroid pore shape distributed gradually through the height of scaffold (global porosity equals

70%) (right) (data from Olivares et al. [

5

])

The mechanical parameters computed in the scaffold surface are considered as

the stimuli or signals felt by the cells attached. Dependent on the stimuli magni-

tude (strain for example), the stimuli will alter cell proliferation or phenotype

differentiation. Generally, for bone tissue engineering applications a compressive

load is applied to determine the strength and the strain distribution in the scaffold

wall surface (see Fig.

3

). The effect of mechanical stimuli was studied through

micro-FE models for macroporous CaP cement and for a porous glass ceramic

scaffold. The octahedral shear strain distribution on a two dimensional section of

both samples is shown in Fig.

3

a; higher strains are found in areas close to the

pores with magnitudes up to 0.75% for the application of a compressive strain of

0.5% [

9

]. The strain distribution throughout the section is quite inhomogeneous

due to the inhomogeneous pore distribution.

Under a compressive load equivalent to a uniaxial strain of 0.5%, the structures

shown in the Fig.

3

b presented a higher proportion of material experiencing

Search WWH ::

Custom Search