Biomedical Engineering Reference

In-Depth Information

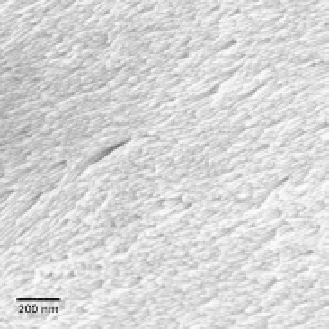

(a)

(b)

Figure 2.13

Effect of template degradation processing on Pt nanowire

stability (SEM micrographs). (a) Removal by rinsing in organic solvent and

drying can lead to complete collapse of the nanowire array. (b) Dry etching

by UV-ozone or O

2

plasma etching leaves the wires standing. Viewing

°

angle 45

.

Removal of the polymer matrix in Fig. 2.12b was achieved by UV-

ozone etching after electrochemical deposition. At such high aspect

ratios (diameter 12 nm, length 800 nm) the wires are somewhat

unstable even after dry etch processing. A much greater stability

problem is encountered when the array is exposed to processing

with a liquid phase. Fig. 2.13 shows how rinsing away the polymer

template in organic solvent and simply allowing the film to dry leads

to extensive collapse of the array, most likely caused by capillary

forces in the liquid solvent during drying.

2.4.4.3 Polymeric nanowire replicaion

The great attraction of electrochemical deposition as a means of

BCP replication is the broad range of potential filling materials. Russell

et al.

demonstrated deposition of conducting polypyrrole (PPy)

nanowires into the pores of a 100 nm thick PS-

-PMMA template

on ITO glass using lithium perchlorate in propylene carbonate as

a supporting electrolyte [79]. The template was vertically aligned

on a polymer brush neutralized substrate by the addition of low

molecular weight PMMA homopolymer (Section 2.3.1). Open pores

b

Search WWH ::

Custom Search