Biomedical Engineering Reference

In-Depth Information

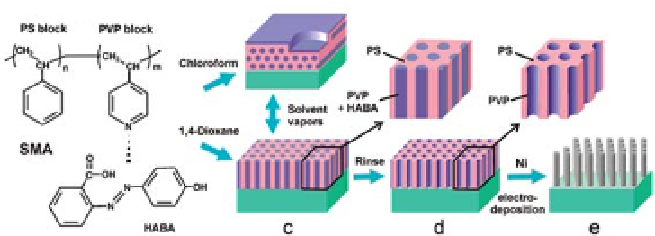

weight additive with the copolymer, chosen to segregate selectively

into one phase. After microphase separation (also typically modified

by the presence of a further component) the molecule can be

released from the structure by soaking in a selective solvent for the

host copolymer block. The copolymer microphase is not destroyed

providing that the majority component remains insoluble. Two

well-studied systems of this type are poly(vinylpyridine) (PVP)

containing copolymers hosting either 2-(4-hydroxybenzeneazo)

benzoic acid (HABA) or 3-pentadecylphenol (PDP) molecules [70,

71]. To date, this method has only been applied in very thin layers

(~40 nm) where selected solvent interactions can switch orientation

from lying to standing cylinders. Sidorenko

. used these films as

electrochemical templates for 40 nm long standing nickel nanorod

arrays some 8 nm in diameter (Fig. 2.8).

et al

Figure 2.8

-PVP):

small molecule (HABA) assembly. Reproduced with permission from

Ref. [71].

Porous electrochemical templates from copolymer (PS-

b

The same selective dissolution method can in fact be used even

without an additive. When the minority component is selectively

solvated then dried, the chains are left coating the matrix phase of

the majority matrix. In an ultrathin film, the chains also migrate

to cover the free surface on drying, leaving an empty pore in what

was the center of the minority domain. Porous arrays up to around

30 nm thick based on PS-

b

-PMMA [72] (trifluorotoluene as selective

PMMA solvent), PS-

b

-PVP [73] and PMMA-

b

-PVP [57] (ethanol as

PVP solvent) have been created in this way.

Search WWH ::

Custom Search