Biomedical Engineering Reference

In-Depth Information

also be electropolymerized by such template methods [205]. Highly

ordered magnetic nano-scale dot arrays of Ni can be fabricated from

double-templated electrodeposition [206,207]. Patterns of ordered

arrays of spheres with controlled spacing can be electrochemical

deposited by two steps. The double templates were firstly prepared

by self-assembly of PS latex spheres on a gold coated glass substrate.

This primary template was used for the electrodeposition of the

conducting polymer resulting in a macroporous polymer template.

After the deposition of PPy, the PS spheres were dissolved in toluene

leaving a secondary polymer template. The PPy was then converted

into an insulator either by over-oxidation or by undoping at a

sufficiently negative potential. This insulating structure was used

as the template for electrochemical deposition of magnetic material

such as Ni. Electrodeposition of magnetic materials gradually fills

the spherical cavities of the PPy template. Ordered arrays of Ni dots

with quasi-spherical geometry can be fabricated by this way and the

diameter of the dots can be set from 20 nm [207].

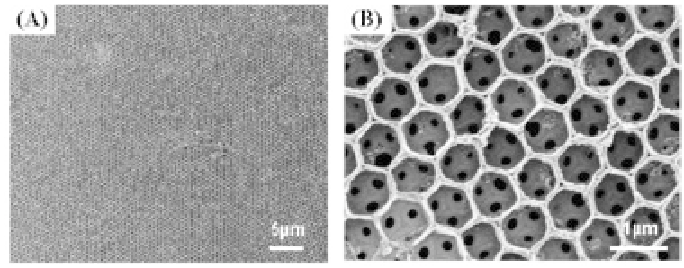

Figure 1.

19

SEM images of PANI inverse opals prepared via cyclic

voltammetry, at low (A) and higher (B) magnification. Scan rate 20 mV/s,

10 scan cycles [208]. Reproduced by kind permission from the publisher.

Ordered 3D arrays of polyaniline (PANI) inverse opals can also

fabricated via electrochemical methods by using colloidal crystals

of polystyrene beads as sacrificial templates as shown in Fig. 1.

19

[208]. Compared with films obtained by chemical synthesis, the

inverse opaline samples obtained by electrochemistry had a much

higher structural quality. Such PANI inverse opals were prepared

by a galvanostatic method at a current density 0.05 mA/cm

. By

adjusting the polymerization time and applied current, this method

2

Search WWH ::

Custom Search