Biomedical Engineering Reference

In-Depth Information

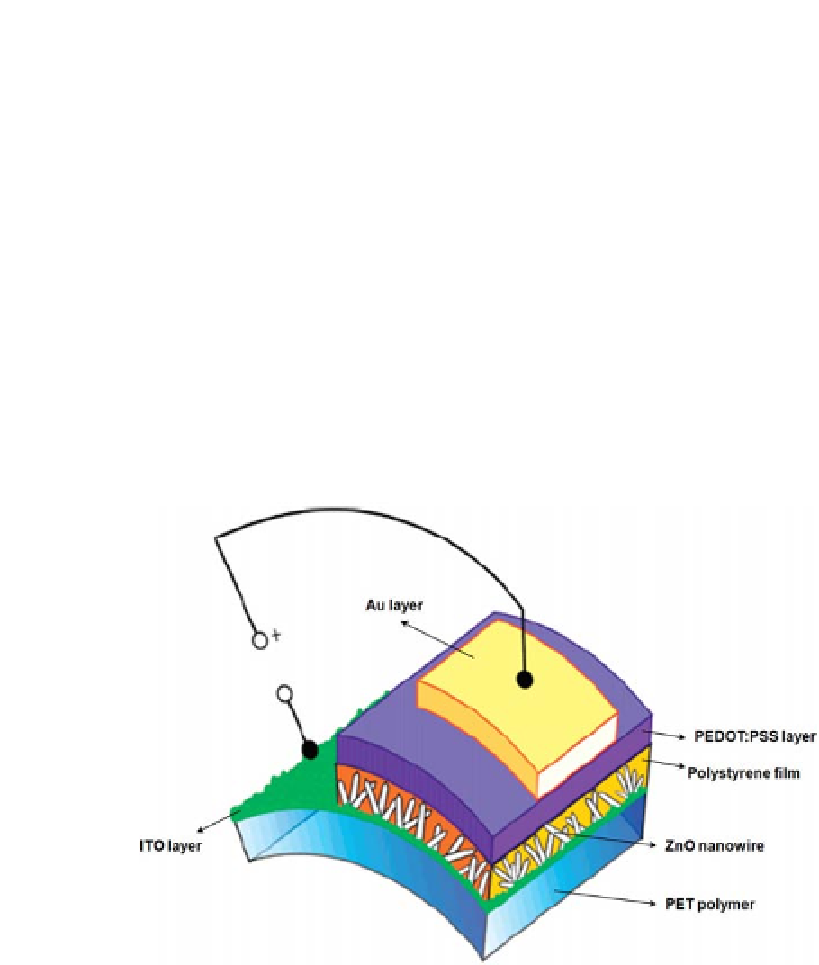

out the space between the ZnO nanowires and produce only a very

thin coverage of the nanowire tips. The polystyrene layer thickness

at the tips can be further reduced by the plasma etching treatment

to make the n-type ZnO tip junctions outside. A top contact

consisting of a thin p-type poly(3,4-ethylene dioxythiophene):

poly(styrenesulfonate) (PEDOT:PSS) layer and an evaporated Au

film are provided to serve as the hole injection anode in the LED.

A flexible LED can be realized when electrochemical depositing

the ZnO nanowire on flexible transparent polymer substrates (e.g.

polyethylene terephthalate, PET) coated with indium-tin oxide

(ITO) [140]. The infrastructure of such flexible LED is illustrated in

Fig. 1.

14

. This device exhibits electroluminescence over most of the

visible spectrum at moderate forward bias.

Design scheme for a flexible LED structure consisting of

vertically oriented single crystalline nanowires grown electrochemically

on a polymeric ITO-coated substrate. The top contact consists of p-type

polymer (PEDOT:PSS) and an evaporated Au layer. Light is emitted

through the transparent polymer [140]. Reproduced by kind permission

from the publisher.

Figure 1.14

Search WWH ::

Custom Search