Biomedical Engineering Reference

In-Depth Information

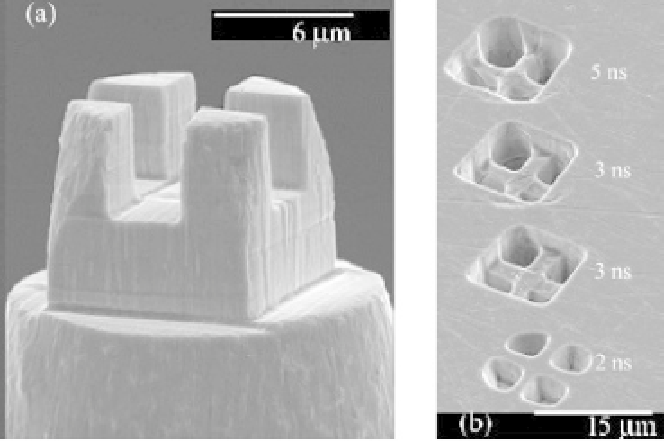

between tool and workpiece. Examples of patterns made with the

2×2 array of cubes tool are shown in Fig. 1.

9b

. This indicates that the

feature resolution improves with decrease in pulse duration.

Figure

1.9

Scanning

electron

micrographs.

(a)

Tungsten

tool;

-

(b) machined Ni substrate. Experimental conditions:

U

=

1.7 V,

U

tool

=

sub

-

1.0 V, pulse duration indicated, 2 V amplitude, 1:10 pulse to pause

ratio, and 0.2 M HCl electrolyte. Feature resolution and edge sharpness

increased as pulse duration decreased [114]. Reproduced by kind

permission from the publisher.

3D machining of electrochemically active materials, including

the construction of unconventional island patterns on a surface

with nanoscale resolution, was also realized by this method

[95,115-117]. Thus, electrochemical machining can be applied to

microelectromechanical systems (MEMS) [118] and even in the

nanoelectromechanical systems (NEMS). Electrochemical methods

can realize the nanofabrication in a selective place and make the

complicated 3D nanostructures. Conducting polymers can also be

fabricated in this way. Similar to the electrochemical machining,

by application of short voltage pulses to the tool electrode in the

vicinity of the workpiece electrode, the electropolymerization of

pyrrole can be locally confined with micrometer precision [119]. As

the produced nuclei of conducting polymers will grow preferentially

vertically to the surface, fiber-like morphologies were found in

Search WWH ::

Custom Search