Biomedical Engineering Reference

In-Depth Information

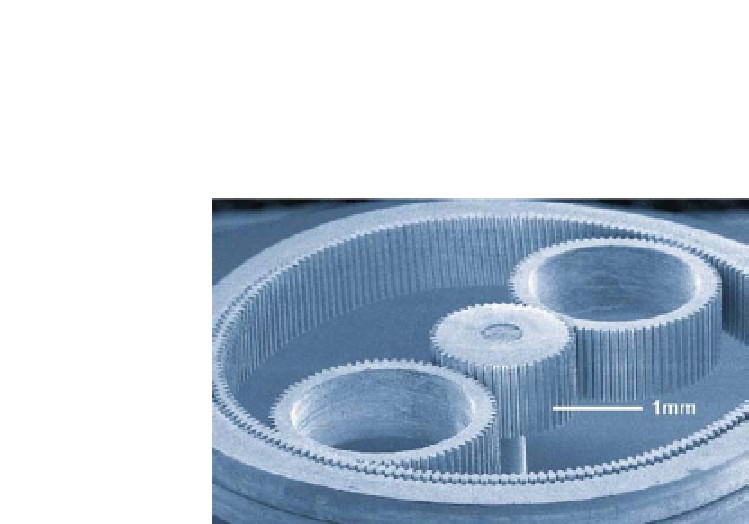

deep lithography, electrodeposition, and molding process steps.

LIGA offers high potential regarding miniaturization, freedom of

design, and mass production. Micro-gear system produced from a

nickel iron alloy by means of LIGA has been shown in Fig. 1.

7

.

Figure 1.7

Micro-gear system produced from a nickel iron alloy by means

of LIGA technology (Source: Micromotion, IMM) [108]. Reproduced by kind

permission from the publisher.

However, the ultraprecise microstructures with extreme aspect

ratio could only be generated by deep X-ray lithography. Difficulties,

for example, in the access to synchrotron radiation facilities have

limited the commercialization of LIGA technique in mass fabrication.

1.7 MICRO- AND NANO-MACHINING BY ULTRASHORT

VOLTAGE PULSING TECHNIQUE

Use of electrochemistry in micro-machining has been a matured area

[111]. In contrast to the conventional processes of electrochemical

micromachining, where the gap between the electrodes is usually

0.1 mm and direct current is applied, a novel electrochemical

microfabrication method using a gap in “μm” range and very short

voltage pulses of some tens of nanoseconds was developed. The

short pulse confines electrochemical processes correspondingly,

removal of material to a very narrow volume to enable a precise

nanomachining. Ultrashort pulses can be employed to machine

conducting materials with lithographic precision [112]. Resolution

can be improved significantly through the use of ultrashort voltage

Search WWH ::

Custom Search