Biomedical Engineering Reference

In-Depth Information

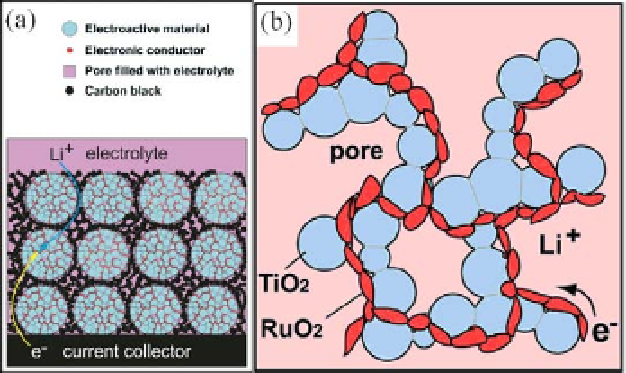

the prepared nanocomposite shows superior high rate capability

when used as anode material for lithium-ion batteries [34]. As can

be seen in Fig. 6.8, the nanoscopic network structure is composed

of a dense net of metalized mesopores that allow both Li

+

and

to migrate; thereby, the effective diffusion length is reduced.

Moreover, this network with mesh size of about 10 nm can be

overlapped by another net with similar structure on the micron-

scale formed by the composite of the mesoporous particles and

the conductive admixture. Besides, RuO

e

-

formed during

Li insertion also allows for quick Li permeation, and this can be

proved by the fact that at a very high charge/discharge rate of

30 C, the specific charge capacity of the composite is 91 mAh g

or Li

RuO

2

x

2

-

1

,

nine times larger than that of the original mesoporous TiO

spheres

2

(10 mAh g

-

1

).

nanocomposites. (b) Schematic

illustration of the self-wired path of deposited RuO

Figure 6.8.

(a) Sketch of TiO

:RuO

2

2

nanoparticles (all

reproduced with permission from [34], copyright 2007, Wiley-VCH Verlag

GmbH & Co. KGaA).

2

The concept of hierarchical 3D mixed conducting networks

has also been successfully used in constructing high rate cathode

materials such as LiFePO

. It has been found that benefiting from the

combining use of carbon and nanometer-sized RuO

4

as electronic

interconnects, the kinetics and rate capability of the composite of

C-LiFePO

4

2

-RuO

are significantly improved [67].

2

Search WWH ::

Custom Search