Biomedical Engineering Reference

In-Depth Information

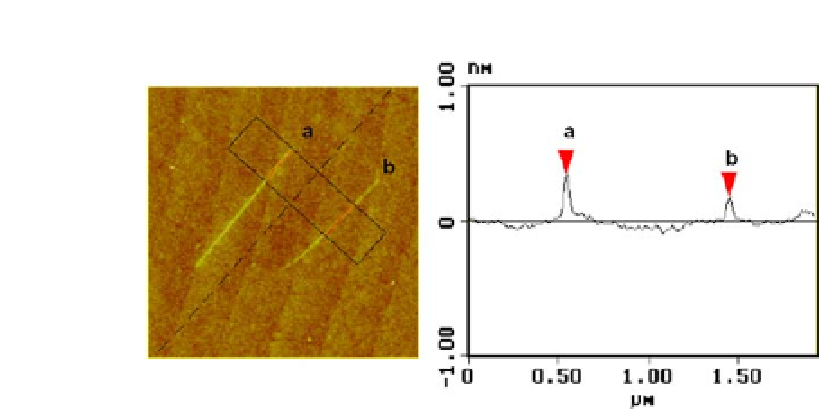

Figure 1.5

AFM image and height profile of two Pt lines drawn at different

scan speed. (a) Line at 10 nm/s and (b) line at 20 nm/s. The voltage applied

at the tip is 3 V for both lines and the relative humidity is 43% [106].

Reproduced by kind permission from the publisher.

Electrochemical AFM “dip-pen'' nanolithography has

significantly expanded the scope where DPN nanofabrication can

be applied. It combines the versatility of electrochemistry with the

simplicity and power of the DPN method to produce nanostructures

with high resolution. Electrochemical STM-based methods require

that the substrates be metallic, but substrates used in EC-DPN do

not have to be metallic since the control feedback of the AFM does

not rely on the current between the tip and surface. Si wafers coated

with native oxide provides enough conductivity for the reduction

of the precursor ions. This development significantly expands the

scope of DPN lithography, making it a more general nanofabrication

technique that not only can be used to deliver organic molecules

to surfaces but is also capable of fabricating metallic and

semiconducting structures with precise control over location

and geometry. Local electrochemical deposition of freestanding

vertically grown platinum nanowires was demonstrated with a

similar approach, electrochemical fountain pen nanofabrication (EC-

FPN) [107]. The EC-FPN exploits the meniscus formed between an

electrolyte-filled nanopipette (“the fountain pen”) and a conductive

substrate to serve as a confined electrochemical cell for reducing and

depositing metal ions. Freestanding Pt nanowires were continuously

Search WWH ::

Custom Search