Biomedical Engineering Reference

In-Depth Information

Electrolyte:

Li

+

, EC, DEC, PF

6

Li

+

(a)

e

−

External circuit:

e

−

Li

+

+ ntTiO

2

+ e

−

(b)

p

δ

Li

x

ntTiO

2

δ: 50

−

150 nm

p: 20 nm

L: 600

−

900 nm

L

Figure 5.16

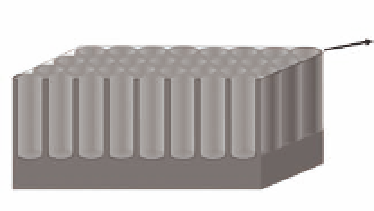

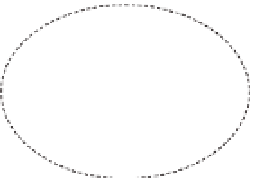

(a) Schematic representation of the self-organized titania

nanotubes used for the assessment of the specific area. (b) Transport path

of lithium ions and electrons in mesoporous titania nanotube.

It can also be noted that the ratio between the irreversible

capacity of the amorphous and the annealed materials is around 5.

This difference can be explained by the fact that annealing treatment

of the amorphous electrode removes structural and chemical defects

that act as Li

ion traps, which are responsible for the irreversible

insertion of Li

+

. This explanation is for titania nanotubes with 900

nm, but it can be also applied for the shorter nanotubes show above.

The cycle performance of as-formed and annealed ntTiO

+

-based

2

) is illustrated

in Fig. 5.17 for 50 cycles. First, these results suggest that ntTiO

2

electrodes at different kinetics (5, 20 and 100

μ

A cm

-

2

can be used as an alternative electrode for rechargeable Li-ion

microbatteries. The specific capacity obtained for the as-prepared

samples is higher than for the annealed materials confirming that

the amount of lithium ions inserted into amorphous ntTiO

2

is higher

than in the crystalline structure. The highest specific capacity

is obtained with as-prepared ntTiO

layers using a relative slow

2

or C/8), which delivered a maximum reversible

capacity of 77 μAh cm

kinetic (5 μA cm

-

2

after

50 cycles (see Fig. 5.17a). The average capacity loss of 0.45 μAh cm

-

2

after the first cycle and 55 μAh cm

-

2

-

2

Search WWH ::

Custom Search