Biomedical Engineering Reference

In-Depth Information

3.0

3.0

(a)

(b)

Amorphous ntTiO

2

(600 nm)

onto Si substrate

Crystallized ntTiO

2

(600nm)

onto Si substrate

50

th

1

st

2.7

2.7

50

th

3

rd

2

nd

1

st

2.4

2.4

2.1

2.1

1.8

1.8

1.5

1.5

1.2

1.2

50

th

3

rd

2

nd

0.9

1

st

3

rd

1

st

50

th

2

nd

0.9

0

20

40

60

80

100

120

140

160

180

200

0

20

40

60

80

100

120

140

160

180

200

220

Areal Capacity /

µ

Ah cm

-2

Areal Capacity /

µ

Ah cm

-2

200

(c)

Si substrate

180

Amorphous ntTiO

2

, 5

µ

Acm

-2

Amorphous ntTiO

2

, 100

µ

Acm

-2

Crystallized ntTiO

2

, 5

µ

Acm

-2

Crystallized ntTiO

2

, 100

µ

Acm

-2

160

140

120

100

80

60

40

20

0

0

10

20

30

40

50

Cycle Number / n

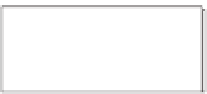

Figure 5.13

Galvanostatic discharge/charge curves during the 50 cycles of

ntTiO

nanotube layers obtained onto Si substrates: (a) as-prepared, and

after thermal treatment at 450°C (b). (c) Evolution of its areal capacity as a

function of cycle number using a kinetic of 5 (C/8) and 100 (2.5C) µA cm

2

−2

.

Other possible reasons for the high experimental capacity

values are the high surface area and highly organized 1D structure

of titania nanotube layers. When a rate of 100

μ

(2.5C) is used,

the reversible and irreversible capacities are lower than at a rate of

5

A cm

−2

μ

, but the capacity retention for crystalline is around 96%

(close and star-shaped symbols in Fig. 5.13c; Table 5.1).

A similar behavior was found in the galvanostatic curves of

ntTiO

A cm

−2

samples with 600 nm length manufactured on commercial

Ti foil (Fig. 5.14). The main difference between amorphous and

crystalline nanotubes resides in the observation of a voltage plateau

during the discharge (1.75 V) and charge (1.95 V) of the cell during

the 50 cycles. Under low kinetics, the amount of lithium inserted

into amorphous (53

2

μ

Ah cm

−2

) is higher than in crystalline ntTiO

2

μ

(49

Ah cm

−2

), and they exhibit after 50 cycles an efficiency of 70%

Search WWH ::

Custom Search