Information Technology Reference

In-Depth Information

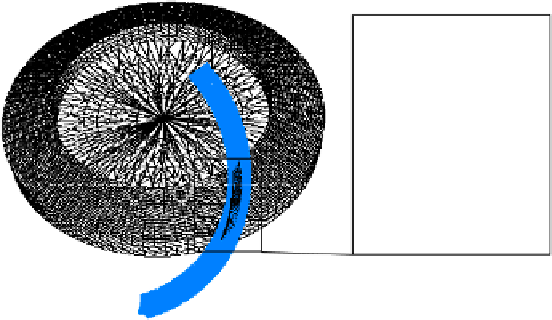

workpiece

tool

enveloping

body

penetrated volume =

undeformed chip

geometry

Fig. 5.

3D penetration calculation of triangulated surfaces

3

Calculated Characteristic Values for Tool Wear Analysis

3.1

Current Characteristic Values for Process Analysis

Chip thickness h

cu

and the working length l

e

are characteristic values, besides the

cutting forces, for description and analyzing the bevel gear cutting process according

to [3-4], see figure 6. The chip thickness represents the thickness of the undeformed

chip at a certain point on the cutting edge. The working length represents the cutting

path i.e. the contact length between the tool and the workpiece during the cutting.

Investigations from [3-4] and [8] show that also the characteristic values like the

working rake angle γ

e

and relief angle α

e

have a significant influence on the tool wear.

Especially the flank wear of the tool is not only influenced by the chip thickness h

cu

and the working length l

e

, but also by the geometry of the cutting edge. The cutter

geometry inter alia is determined by the rake and relief angle of the cutter. These

angles are defined in the German Standard DIN 6580 and DIN 6581 [9-10].

As a conclusion of the state of the art investigations it can be stated that there is

partly the possibility to analyze the tool wear by means of the current characteristic

values. But there is no sufficient approach yet for a prediction of tool wear in bevel

gear cutting.

In industrial application there are different tool concepts. One of the concepts is the

alternating half profile blades. They are separated into outside and inside blades, see

figure 7. Both blades are defined as a blade group. One blade group cuts the contour

of one gap including gear root and flanks. The outside blade cuts the concave flank

and the inside blade cuts the convex flank of the gear gap. From this typical two-flank

chips are cut. The removed material on the flanks respectively the chip thickness

h

cu,flank

depends inter alia on the chip thickness on the tip h

cu,tip

and the pressure angle

δ

OB

or δ

IB

of the tools:

h

cu,flank

= h

cu,tip

· sin(δ)

(2)

Search WWH ::

Custom Search